As we have seen in our previous blog, there are 3 essential components of Ultrasonic Cleaning Machines. These need to be set at a certain frequency to produce mechanical vibrations. These vibrations then create an ultrasonic effect called ‘cavitation’ inside the fluid and help to remove the fine particles. In this article, we will see the physics of the ultrasonic cleaning effect and the application of a certain frequency suitable for components from various industries.

“Effective cleaning of parts with the ultrasonic cleaning machine depends on matching the system frequency to the parts to be cleaned and to the contamination to be removed”

Low frequencies deliver precise cleaning results for the complex parts having unpolished surfaces and small particle size. For even smaller particles size and more precision, an intermediate frequency range is used. And when particle sizes are microscopic, the higher range of frequency range is used. In some cases, the surface of the part is more sensitive and thus the higher frequency is used to ensure that the cleaning process doesn’t damage the parts and delivers ultra-fine cleaning quality.

The Physics behind Ultrasonic cleaning technology

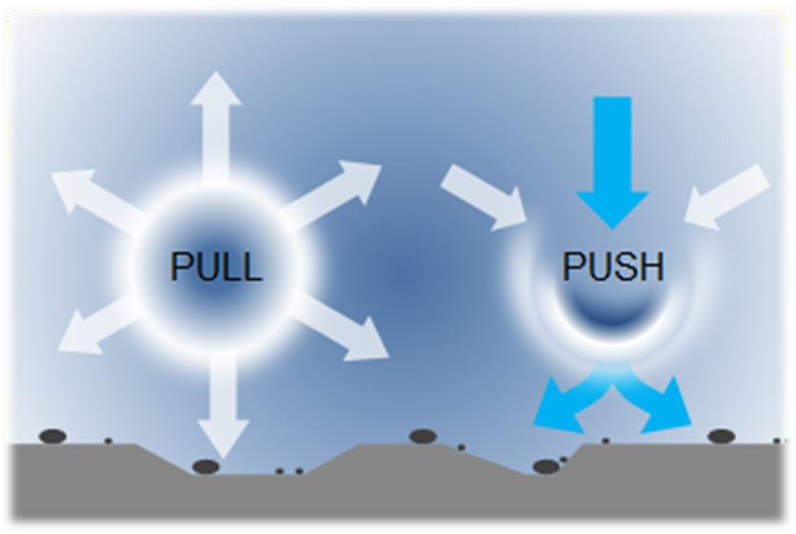

Ultrasonic cleaning technology uses low and high-frequency vibrations in a fluid to form vapour bubbles which then creates turbulence. Thus, it creates “cavitation effect”, which can be utilized in cleaning in two ways as below,

Cavitation: Micro Jet

In this case, low- and high-pressure changes in the fluid causes growth and the implosion of vapour bubbles. The implosion results in microjet with locally high temperature and pressure. This facilitates dislodge the contaminants adhering to the surface of the part when it is submerged in an ultrasonically activated fluid. This cavitation effect is more effective when there is low frequency.

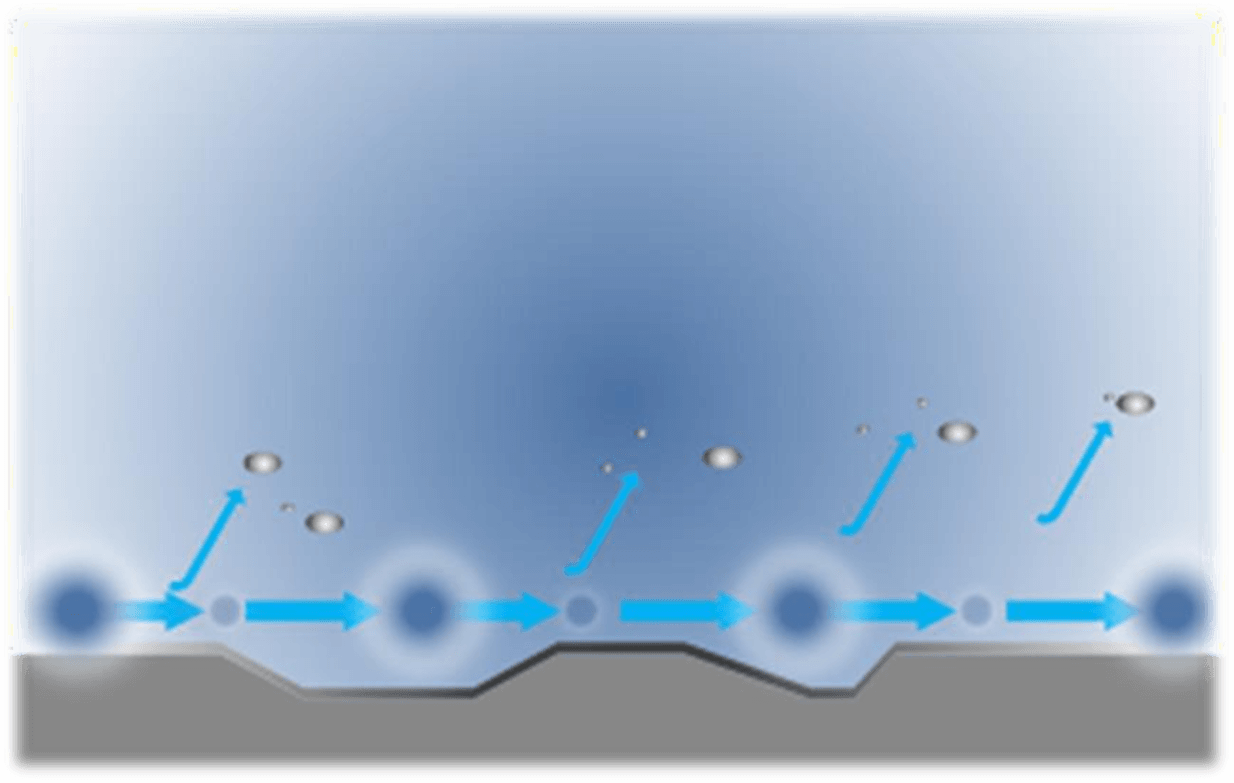

Fluid flow: Micro stream

In this case, these bubbles created by the Push-pull effect in fluid do not explode or collapse but they direct the fluid flow near to the surface and cavities of the part and carry away the contamination. This effect is most effective when the high frequency is used.

Both effects can occur at any high or low frequency, but its relevance for the cleaning will change with the frequency.

How to select the right frequency for your application?

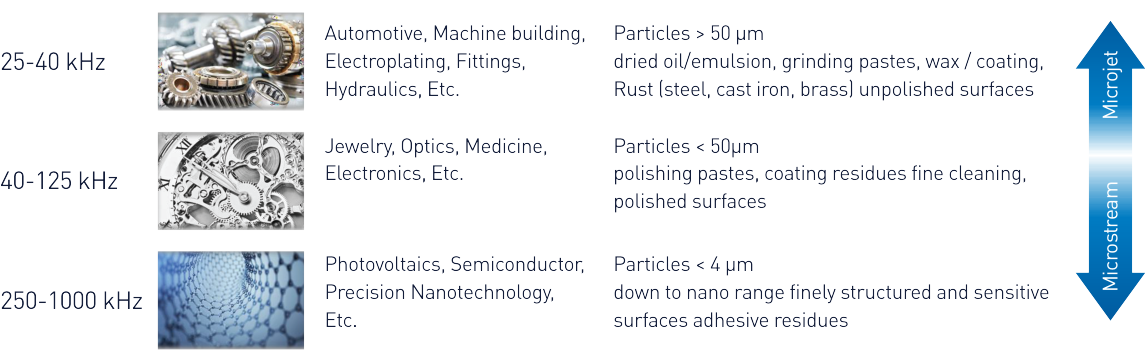

Normally, an Ultrasonic cleaning machine utilizes frequencies that vary from 15 kHz to 1000 kHz. The lower range of frequencies is typically used in the cleaning of automotive components. Selecting these frequencies depends on the type of contaminants and the minimum particle size requirement. Let’s look at the available frequency ranges, what they can accomplish and the best frequency range for various industries,

Low frequencies for ultrasonic cleaning are usually are ranging from 25 to 40 KHz and suitable to remove contamination on an unpolished surface such as dried oil/ emulsion, grinding pastes, wax/coating, Rust (Steel, Cast Iron, Brass). Ideally, 25 KHz frequency is used to clean unpolished surfaces of applications from the Automotive, Manufacturing, Electroplating, Hydraulics industry.

The frequencies ranging from 40 to 125 KHz are adapted to remove the contamination such as polishing pastes, coating residues below 50 μm etc. This applies mainly to the applications in Jewellery, Optics, Medicine and Electronics industry where the contamination is smaller and occurs on the polished surface.

For particles below 4 microns from the Nano range on highly sensitive surfaces, a higher frequency above 250 KHz to 1000 KHz is used. This high frequency range delivers a very precise and gentle cleaning effect which is expected for the applications in Photovoltaics, Semiconductor and Nanotechnology industry. Whenever there is an ultra-fine cleaning requirement from High Tech and High Purity industries, the higher frequencies being used.

Choosing the right ultrasonic frequency for your cleaning machine strikes a balance between particle size requirement and the cleaning application. If you are wondering which frequency would work best for your cleanliness requirement, contact our cleaning experts today. write us on info.india@ecoclean-group.net or Call 020-4620 5007