Industrial Parts Cleaning– Efficient and sustainable solutions suitable for Indian market

Parts cleaning is of vital importance to all types of industries no matter whether you are from the manufacturing, automobile, medical or aerospace industry. Ecoclean India, a subsidiary of SBS Ecoclean Group offers industrial parts cleaning solutions that are specially adapted to the Indian market needs.

Our comprehensive range of parts cleaning machines provides reliable & efficient solutions for virtually all types of cleaning tasks such as removal of oil, grease, emulsion and chips; for parts made of metal, plastic, ceramic and glass. The parts or applications and the kind of contamination or soiling determine the cleaning medium and the type of equipment. To find the right solution for your cleaning task and parts, we also offer cleaning trials on a range of Ecoclean machines with different media (aqueous, hydrocarbon and polar solvents) at our India Test Centre in Pune.

From coarse to intermediate to ultrafine cleaning, our solutions not only provide improved cleaning quality and higher process reliability but also guarantees low running cost and high uptime in your production.

Sales, India

Manoj Velhal

Ecoclean Machines Private Limited Plot T-42, T Block, MIDC Bhosari,

411026 Pune

Phone: +91 (0) 902 826 1666

Email: info.india@ecoclean-group.net

Our Product Portfolio

Ecoclean India is a one-stop solution provider for parts cleaning machines and particle analysis. Our ‘Made in India’ machines are well accepted for precision cleaning of parts for various industries in the Indian market. These machines are built to meet stringent requirements of achieving best Millipore results and particle size as per ISO 16232 and VDA 19 standard.

Some standard trademark component cleaning machines manufactured by Ecoclean India:

An aqueous cleaning system is an environment friendly and cost-effective cleaning solution. Aqueous cleaning systems use water-based agents including alkaline, neutral and acidic cleaners. They are preferable if a large quantity needs cleaning and/or fine and precision cleaning have to be carried out.

EcoCbelt

Beltwasher for cleaning processes comprising up to three stages

EcoCflex 3

Outstanding cleaning quality, maximum flexibility and profitability

EcoCcube

Effective spray cleaning for a variety of applications

A solvent-based cleaning solution is used when there are extremely demanding fine and precision cleaning requirement. The single-chamber cleaning systems are designed for a multi-stage cleaning process – cleaning, rinsing, steam degreasing and vacuum drying.

EcoCcompact

The compact solution for economical and reliable solvent cleaning

EcoCduty

The large-chamber cleaning system for superior cost efficiency

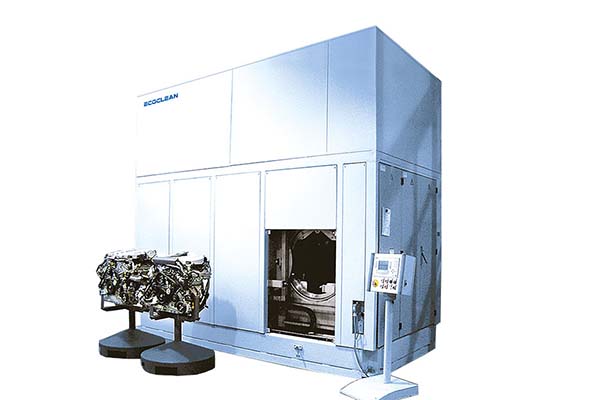

In accordance with the special requirements of the manufacturer, we develop water-based cleaning and deburring systems for large and medium-sized parts, such as those used in the powertrain. With flexible robotic cells and using our own in-house technology centres for innovative cleaning technology, we adapt the different procedures to perfectly suit each individual cleaning task.

EcoCbelt

Beltwasher for cleaning processes comprising up to three stages

EcoCflex 3

Outstanding cleaning quality, maximum flexibility and profitability

EcoCdry

Highly efficient vacuum dryer for the special drying of scooping components

EcoCvelox

High-pressure waterjet deburring efficiently combined with low-pressure cleaning processes

Ecoclean has solutions for all areas of wet chemical cleaning. Whether with water-based cleaners, environmentally friendly hydrocarbons and modified alcohol, chlorinated hydrocarbons or innovative polar solvents, the result is always the same –reliable cleaning of every type of contamination!

Growing demands on the quality of components requires increasingly complex solutions for industrial cleaning. With innovative standard solutions and individually customized cleaning systems, Ecoclean meets international standards on cleanliness in industries as diverse as the production of mechanical components, aviation and space flights, medical technology, the food industry, electronics and laboratory equipment.

Ecoclean provides a fitting solution for every application:

- Automotive systems (e.g. injection, brake and steering systems, turbochargers etc.)

- Mass components (e.g. turning, milling, fasteners, hydraulics etc.)

- Non-metallic parts (e.g. rubber, ceramic, plastic etc.)

- Aircraft and Defence components (e.g. engine and turbine components)

- Precision components (e.g. medical, optical, tools, thin coating, fine mechanics etc.)

EcoCcube

Effective spray cleaning for a variety of applications

EcoCcompact

The compact solution for economical and reliable solvent cleaning

EcoCduty

The large-chamber cleaning system for superior cost efficiency

Ecoclean is one of the leading supplier for surface processing treatment solutions for surface roughening, activation, stripping, de-coring, rust removal, paint stripping, steam cleaning and cavity preservation. This includes the removal of fingerprints on plastic parts before painting or the activation of casting surfaces before thermal coating. We also offer plants and processes for the preservation of components with hot wax and for the stripping of components with high-pressure water up to 2500 bars.

EcoCbooster

For innovative surface processing based on pulsation technology

PulseBoreCenter

Surface processing with EcoCbooster technology

Effective deburring and cleaning is essential for ensuring the technical cleanliness of industrial parts. It is also essential for the quality of subsequent processes such as bonding, sealing and assembly as well as for perfect product function. This process also meets the special demands of selective cleaning and surface treatment for the e-mobility and e-car division. To meet cleaning and deburring needs, we offer machines with a capability of high-pressure waterjet deburring combined with low-pressure processes for cleaning.

EcoCvelox

High-pressure waterjet deburring efficiently combined with low-pressure cleaning processes

The function of industrial cleaning and degreasing covers a wide range of applications across almost every possible industry, from the production of mechanical components, parts of e-mobility, to parts for the aerospace industries or precision components for the medical and optical industries. Ecoclean India offers standard trademark as well as individually customized parts cleaning machines for all types of cleaning requirements, be it parts made of metal, plastic, ceramic or glass.

As a market leader in the field of industrial component cleaning and surface finishing technology, we offer aqueous and solvent-based cleaning solutions in several cleaning requirements. Our industrial parts cleaning machines and solutions have the capability to clean pars used in practically all applications with the potential of spray cleaning, immersion cleaning, ultrasonic cleaning, vapour degreasing, dry cleaning or injection flood washing.

UCMCombiLine

Cleaning of small-sized parts efficiently - across all industries

EcoCbelt

Beltwasher for cleaning processes comprising up to three stages

EcoCflex 3

Outstanding cleaning quality, maximum flexibility and profitability

EcoCcube

Effective spray cleaning for a variety of applications

EcoCcompact

The compact solution for economical and reliable solvent cleaning

EcoCduty

The large-chamber cleaning system for superior cost efficiency

EcoCdry

Highly efficient vacuum dryer for the special drying of scooping components

EcoCbooster

For innovative surface processing based on pulsation technology

PulseBoreCenter

Surface processing with EcoCbooster technology

EcoCvelox

High-pressure waterjet deburring efficiently combined with low-pressure cleaning processes

Whenever there is ultrafine cleaning requirement we offer precision cleaning solutions having a system which uses multi-stage immersion-type ultrasonic cleaning lines for the medical, optical, fine mechanical and coating industries. With state-of-the-art machines from our group company UCM AG from Switzerland, we meet the highest standards of substrate cleanliness.

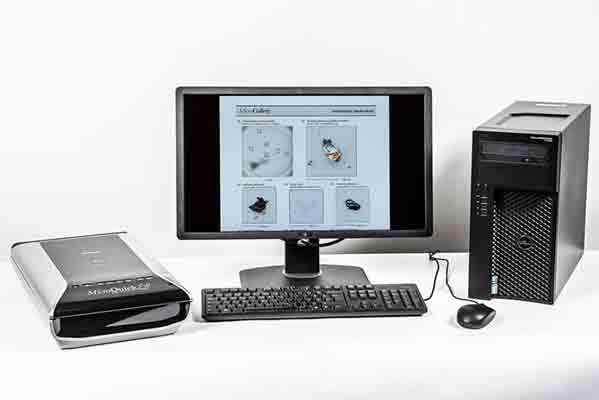

We offer one-of-a-kind Ultra-Fast Particle Scanner for parts cleanliness testing. A high-end component cleanliness testing device that determines particles size and distribution on a membrane and delivering cleanliness results as per ISO – 16232 and VDA – 19 standards. This scanner is used to measure the number, size, shape and reflection of residual dirt particles within just a few minutes.

MicroQuick Particle Scanner

Ultra-Fast Particle Scanner for parts cleanliness testing