In today’s world, achieving microscopic cleanliness is crucial across various industries. From delicate medical instruments to grimy automotive parts, removing dirt, contaminants, and grease is essential for optimal performance and longevity. This is where ultrasonic cleaning machines emerge as a revolutionary solution.

What are Ultrasonic Cleaning Machines?

Ultrasonic cleaning machines utilize high-frequency sound waves to generate cavitation in a cleaning solution. Cavitation describes the rapid formation and collapse of microscopic bubbles within the liquid. As these bubbles implode, they create intense scrubbing forces that dislodge even the most stubborn contaminants from the surfaces of submerged objects.

Benefits of Ultrasonic Cleaning Machines

Ultrasonic cleaning offers a multitude of advantages over traditional cleaning methods:

- Superior Cleaning Power: Ultrasonic waves reach microscopic crevices and blind holes, ensuring a more thorough clean than manual methods or even submersion alone.

- Gentle Yet Effective: Unlike harsh chemicals or abrasive brushes, ultrasonic cleaning is gentle on delicate parts, making it ideal for intricate components.

- Reduced Labor Costs: Ultrasonic cleaning automates the cleaning process, minimizing manual labor requirements and saving time.

- Environmentally Friendly: Many ultrasonic cleaning solutions are water-based and reusable, minimizing the need for harsh chemicals and reducing environmental impact.

- Improved Efficiency: By ensuring parts are thoroughly cleaned, ultrasonic cleaning can enhance equipment performance and lifespan.

Applications of Ultrasonic Cleaning Machines Across Industries

The versatility of ultrasonic cleaning makes it a valuable tool in a wide range of industries:

- Medical & Dental: Ultrasonic cleaners effectively sterilize surgical instruments, dental tools, and other medical equipment, ensuring patient safety and hygiene.

- Automotive: Mechanics can use ultrasonic cleaners to remove grease, grime, and carbon deposits from carburetors, fuel injectors, and other intricate parts.

- Jewelry & Eyewear: Ultrasonic cleaning is ideal for restoring the shine and brilliance of delicate jewelry, watches, and eyeglasses without damaging the materials.

- Electronics: Printed circuit boards, electronic components, and sensitive equipment can be safely and effectively cleaned using ultrasonic technology.

- Aerospace & Defense: Critical components in aircraft and defense systems require meticulous cleaning, a task perfectly suited for ultrasonic machines.

- Manufacturing: Ultrasonic cleaning ensures parts are free of contaminants before assembly, reducing the risk of product defects.

- Optics & Photonics: Ultrasonic cleaners remove dust, oil, and other contaminants from lenses, prisms, and other optical components, ensuring optimal performance.

Choosing the Right Ultrasonic Cleaning Machine

Selecting the right ultrasonic cleaning machine for your specific needs depends on several factors:

- Tank Capacity: Consider the size and quantity of parts you need to clean regularly.

- Cleaning Power: The wattage of the ultrasonic cleaner determines the intensity of the cleaning action. Higher wattage is suitable for heavily soiled parts.

- Frequency: Lower frequencies (around 25 kHz) provide stronger cleaning power for tougher contaminants, while higher frequencies (around 40 kHz) are ideal for delicate objects.

- Cleaning Solution: Choose a cleaning solution compatible with the materials being cleaned and your industry’s regulations.

Optimizing Ultrasonic Cleaning

To maximize the effectiveness of your ultrasonic cleaning machine, follow these tips:

- Pre-clean heavily soiled parts to remove large debris before ultrasonic cleaning.

- Use the correct cleaning solution for the specific materials and contaminants.

- Maintain proper cleaning times and temperatures as per the manufacturer’s instructions.

- Dispose of cleaning solutions responsibly according to local regulations.

Conclusion

Ultrasonic cleaning machines offer a powerful, versatile, and eco-friendly solution for achieving microscopic cleanliness across various industries. By understanding the technology’s benefits, applications, and selection factors, you can leverage ultrasonic cleaning to enhance your cleaning processes, improve efficiency, and ensure the longevity of your equipment.

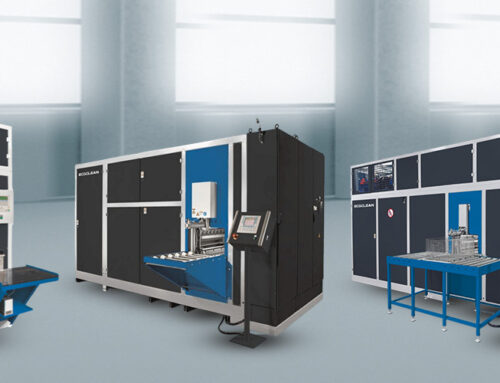

For further information on Ecoclean India’s ultrasonic cleaning machine selection and expert advice, contact us today!