Table of Contents:

1.Understanding the Importance

2. Methods of Cleanliness Analysis

3. Key Points to Consider

4. Preventing Contamination

5. Conclusion

Introduction:

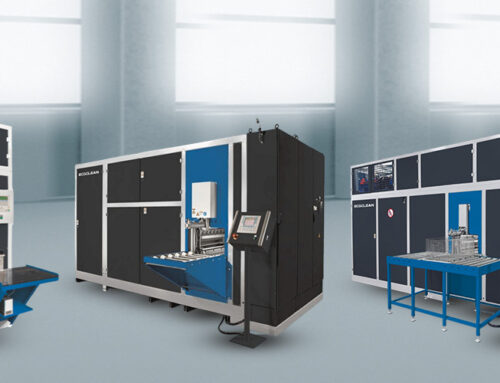

At EcoClean, we know that the level of cleanliness is a key factor in the industrial manufacturing processes. Be it for regulatory compliance or smooth functioning of components, cleanliness analysis is an integral component of our quality assurance procedures. One of the most frequently used quantitative methods of particle contamination determination is the Millipore test or gravity method. In this blog, we’ll provide you with the essentials that should be taken into consideration during Millipore testing in order to achieve reliable and precise results.

Understanding the Importance:

The millipore testing is a great tool for analyzing cleanliness of cleaned items by measuring the dirt quantity on their surfaces. It enables us to comply with the purity standards set by VDA and ISO and therefore our products are of the highest quality.

Methods of Cleanliness Analysis:

In addition to the Millipore test, there are different methods of cleanliness analysis, such as particle analysis. Our technology center complies with the requirements of VDA Vol. 19 and ISO 16232 standards to record the technical cleanliness of components precisely.

Key Points to Consider:

- “Proper Handling of Parts” The part needs to be carefully handled and transferred to a clean room quickly in order to prevent contamination.

- Controlled Environment: The laboratory of cleanliness has to be situated in the closed room with restricted access only for the people who were taught to work with the cleaning system.

- Trained Personnel: It is only permissible for those who are trained to handle and then test the parts after cleaning so as to eliminate the possibility of cross-contamination.

- Validated Test Method: It is very critical that the method of test is validated so as to maintain the consistency and reliability of the results.

- Control of Testing Media: The average level of dirt on the equipment and the testing liquid should be controlled, with a blank value of less than 0.1 mg. The blank test must be done regularly.

- Preservation of Millipore Filters: The tested filters must be retained for future reference, and should be identified to ensure traceability.

Preventing Contamination:

To avoid contamination during testing, it’s essential to:

- The gloves and tweezers used should be Teflon coated and powder free for the handling of the parts.

- Divide the parts into clean bags or boxes to avoid the friction and sealing them well.

- Disregard the use of cotton gloves and paper boxes as they will only transport the contaminants unknowingly.

- Keep correct surface finish and traceable identification labels on them.

Conclusion:

The millipore testing is a mechanism for evaluating the cleanliness and the quality of industrial parts. We are determined at EcoClean to live up to our responsibility by ensuring that the products we offer meet the highest standards of quality and performance by following the key points above and strictly following our sanitary protocol. With our commitment to accuracy and dependability, you can rely on EcoClean for all your cleanliness testing requirements.