Gravimetry test and Particle analysis

Steadily increasing requirements for technical cleanliness demand new cleaning analysis techniques.

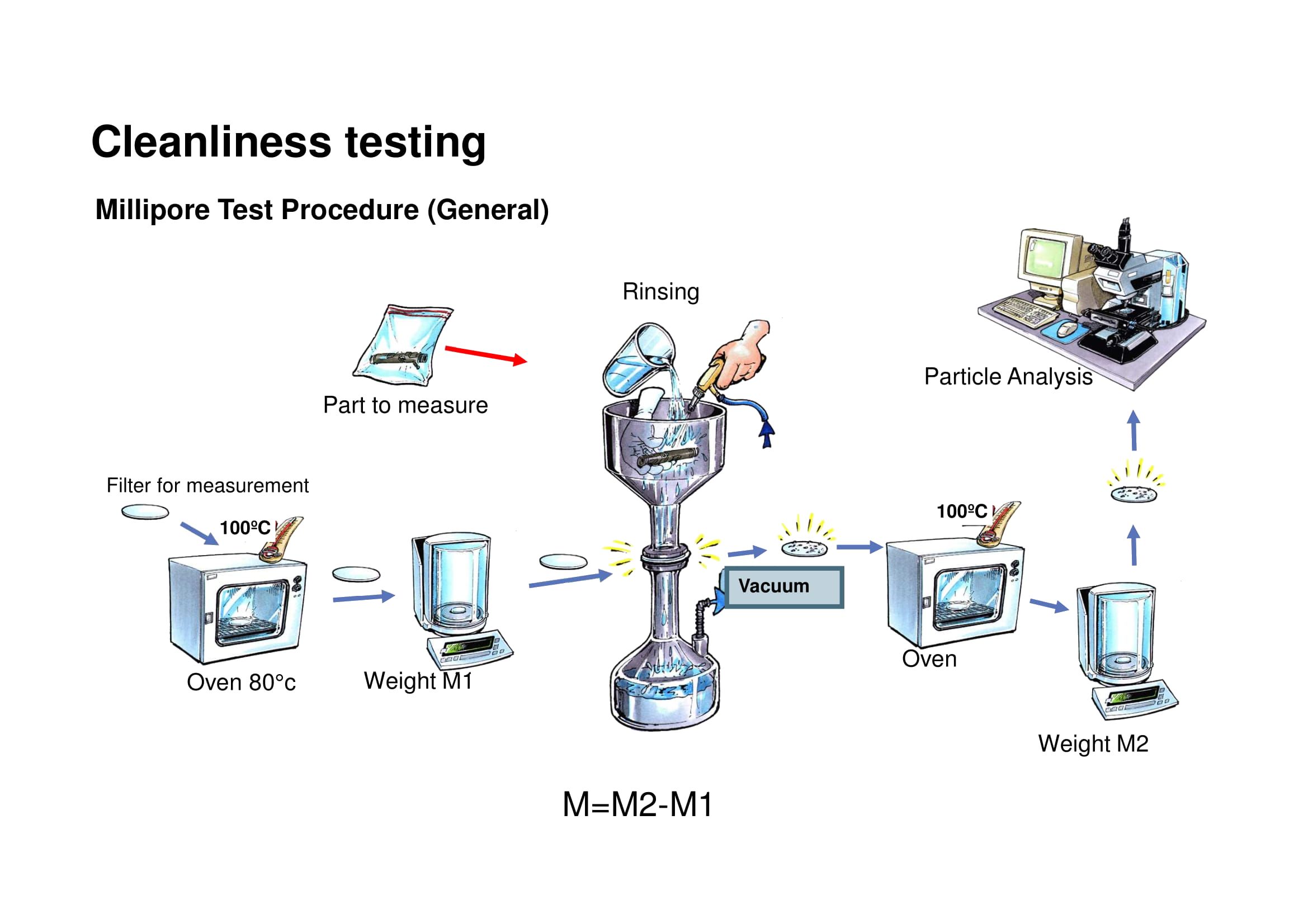

- Gravimetry method, famously known as Millipore test

Gravimetric (also referred to as Millipore) Testing is one method by which a manufacturer can have their parts checked for cleanliness. It is an objective, scientific method that helps to take the guesswork out of meeting cleanliness specifications. Using a flushing solvent and filters, the amount of contamination on a part can be weighed to produce an accurate account of how much contaminant is left after the production washing of the part.

Also called a solvent extraction test, the particles are flushed off the part and collect on the filter membrane paper can be analyzed microscopically using automated scanning particle counters such as a Leica to characterize the size and amount of particulate collected. ISO 1632-10 is one such spec which determines part cleanliness based on particulate size and quantity.

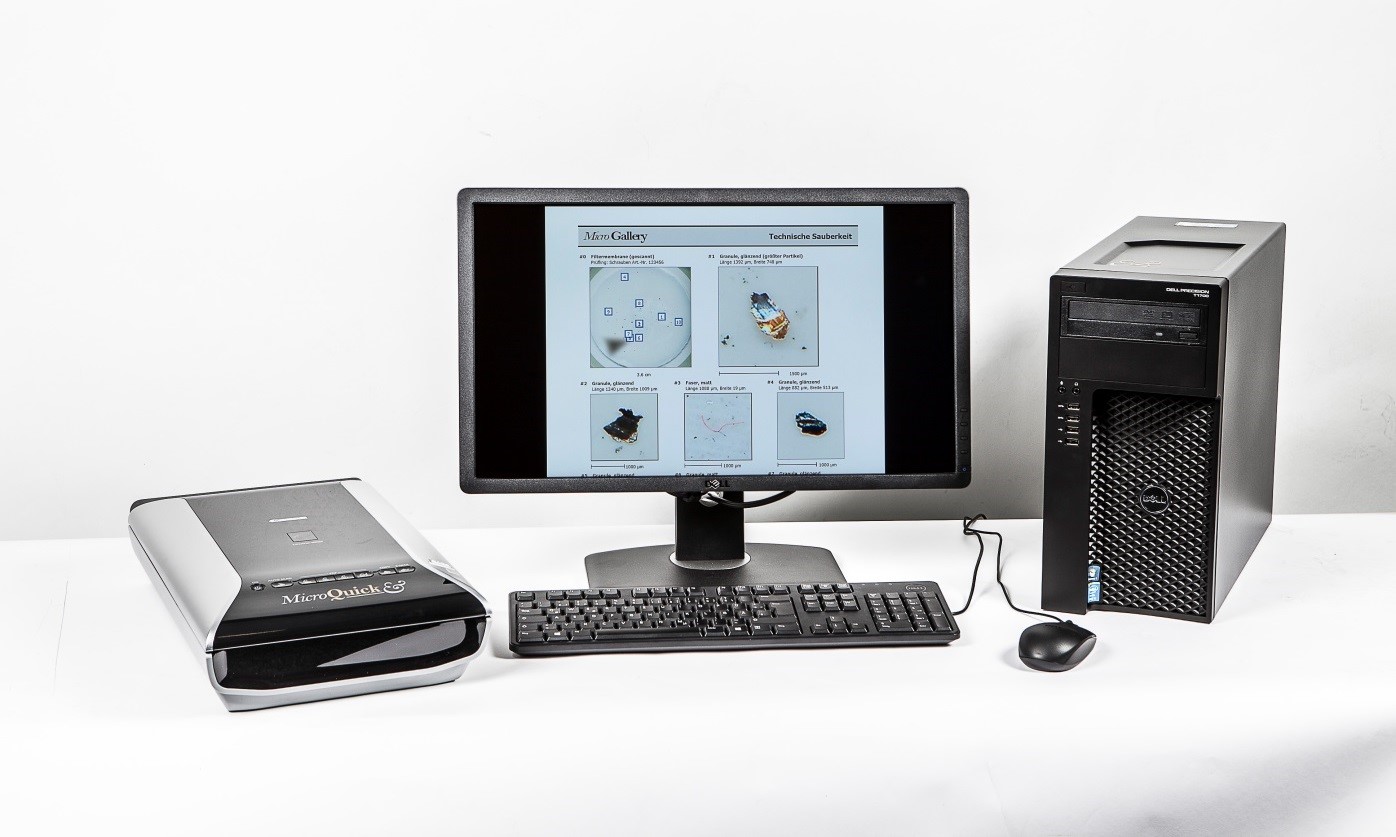

- Particle Analysis

High resolution scanner for particle analysis: Measuring quantity, size, shape and reflection of residual contaminant particles all in one place. Scanning is done in reflected and transmitted light and includes software generated reports analyzing component cleanliness.

Advantages of these Cleanliness testing methods at Ecoclean’s Technology Center:

- Time and cost savings as a result of immediate analysis on-site

- Expert advice and active support on technical cleanliness and it’s different aspects

- Component cleanliness analysis of different components based on VDA 19 and ISO 16232

- Process chain analysis as a basis for optimizing production processes with regard to technical cleanliness

Note: Standards for Analysis should allow a Unification of the practical Performance and improve the Reproducibility and Accuracy of the Results.