Today's industrial parts cleaning processes are built on various value-driven steps. One of these is "Cleanliness Testing", which went on to become a foundation of today's quality management approach. Since the acceptance of a competitive market, the Automotive and Aerospace OEMs', along with their suppliers, as well as MedTech and High-purity applications, have placed high importance on the technical cleanliness of the components. Particularly in the Automobile Industry, this is being analyzed in accordance with ISO 16232 / VDA 19 inspection standards.

In simple terms, technical cleanliness testing is a process to determine and analyze all residual contamination on the part's surface, ensuring that it meets the cleanliness standards defined by the industry or customer. The cleanliness testing process involves extraction, filtration, and microscopic analysis of particulates to determine the number, size, weight, and distribution of residual particles.

Various Cleanliness Testing Methods:

The methods of cleanliness analysis might range from a basic visual inspection to quantified measurements which include Millipore value, particle size, weight etc. Normally these cleanliness testing methods can be categorized into two types, Qualitative and Quantitative. The Qualitative method is a subjective method that mainly involves visual checking and thus doesn't give us clear values of cleanliness. Whereas the Quantitative involves measurement of the level of cleanliness.

Qualitative Methods:

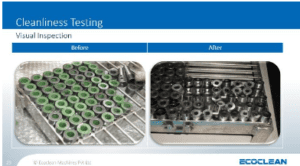

- Visual Inspection

Visual inspection is the method of choice to confirm a visually clean surface. The acceptance criteria vary from person to person, and it is highly dependent on the experience and skill of the person. So generally, this cleaning method can be used before final assembly or after the intermediate cleaning process to check whether the surface is oil-free and visually clean.

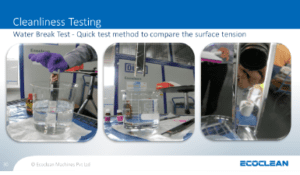

- Water Break Test:

Water Break Test is commonly used after PVD / CVD coating or special plating operations to check the oil-free surface. This test involves the part dipped in pure DM water and observing the flow pattern on the clean surface. It is relatively simple to perform; however, the results rely almost entirely on the eye of a person performing the test. The water break test is also subjective, and it is becoming obsolete as manufacturers embrace new and quantitative methods for highly sophisticated production.

DQuantitative Methods:

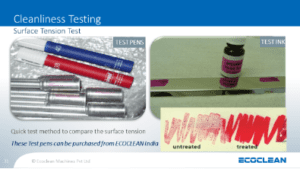

- Surface Tension Test:

This is a quantitative test to determine the surface tension using ink applied on the surface after cleaning. These pens have different calibration values. When applied on the surface, it gives a different stroke pattern on the surface. This behavioral pattern drawn by the test ink pens has a standard range that gives the degree of cleanliness in mN/meter.

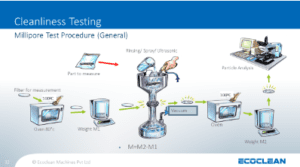

- Millipore Testing

Millipore Testing is a commonly used testing to determine the dirt/particles remaining on the part after cleaning. This test is also known as the Gravimetry test which measures the size and quantity of particulates. The testing set-up contains special filters to collect residual contaminants, Oven for drying the filter, Weighing scale, Millipore Test Flask, and testing media etc.

[check detailed test procedure here, https://ecoclean-india.com/methods-of-cleanliness-analysis/

- Particle Analysis:

Further to the Millipore value, there are additional cleanliness parameters to be analyzed such as particle type (metallic or non-metallic), size, and count per surface or part. The particle analysis method has been introduced as an industry standard and is compliant with the ISO 16232 / VDA 19 standards.

This method uses a particle scanner to evaluate above stated parameters in a simple and quick way. Microquick Particle Scanner is a high-end component cleanliness testing device that determines particle size, shape, and reflection of residual dirt particles on a membrane within just a few minutes. This device scans the membrane, analyzes the particles, and delivers the cleanliness results in just 2.5 minutes along with a report.

[Read more information about MicroQuick Particle Scanner, https://ecoclean-india.com/products/products-microquick-particle-scanner/

At Ecoclean, our expertise lies in superior technology and comprehensive services for industrial parts cleaning. The state-of-the-art technology center in Pune, India is equipped with dedicated machines to conduct cleaning trials and high-end Millipore testing lab inside the cleanroom.

Contact our cleaning experts today at application.india@ecoclean-group.net. We are happy to assist you and find suitable solutions for your cleanliness requirement.