One innovation highlight that has gained further momentum in 2021 is the UCMSmartLine. Roger Kohnen, Business Development Manager Precision Cleaning comments: “The manufacturing, joining and coating technologies have changed. At the same time, increasingly strict regulatory requirements must be met in many markets.” Medical technology, optics and precision and micro-technology, but also the automotive and supplier industries, increasingly demand reliable methods to meet the high demands for particle and film cleanliness – at competitive prices.

With our modular ultrasonic immersion system UCMSmartLine, we can meet these high standards: With up to nine cleaning and rinsing stages, it offers numerous options for solving individual cleaning tasks with the highest demands on component quality.

Modular system for many applications

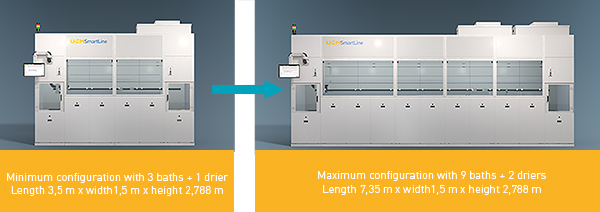

Another plus: the modern modular concept allows highly compact ultrasonic multi-chamber immersion cleaning systems to be realised with three to nine cleaning and rinsing stages for preliminary, intermediate and final cleaning. This means that the system can be individually configured for a wide range of applications and adapted to changing market conditions at any time. Two- and three-stage modules are available for the process steps “cleaning & rinsing” or “cleaning, cleaning & rinsing”, which can be combined as desired. With a further module, two-stage fine and precision rinsing processes with cascaded osmosis or demineralised water can be integrated. The ultrasonic cleaning modules, which are heated and equipped with a filter circuit as standard, can also be adapted to a wide variety of applications. The parts are dried by infrared radiant heat, hot air or under vacuum. Depending on the application, these drying technologies can also be used in combination.

Understanding customer needs

“We always develop our solutions with our customers in mind. Because they always come first for us,” explains Manfred Hermanns, Vice President Sales & Customer Service. “With our UCMSmartLine, we have developed a system solution that can easily be adapted to the individual needs of our customers – without going beyond the budget.”

The advantages of the UCMSmartLine at a glance:

- Modular, multi-stage ultrasonic immersion cleaning system for high to highest cleanliness requirements;

- Variable use of mono, twin or multi-frequency ultrasonics;

- Flexible transport system for optimized throughput and gentle part handling;

- Space-saving design with electrical and control technology integrated into each module;

- High-quality machine enclosure protects parts and personnel from contamination and emissions;

- High adaptability through optional subsequent module expansion;

- Process validation by cleaning tests in the SBS Ecoclean Group worldwide test centers;

- Short delivery times & flexible delivery options (in one piece or modular).