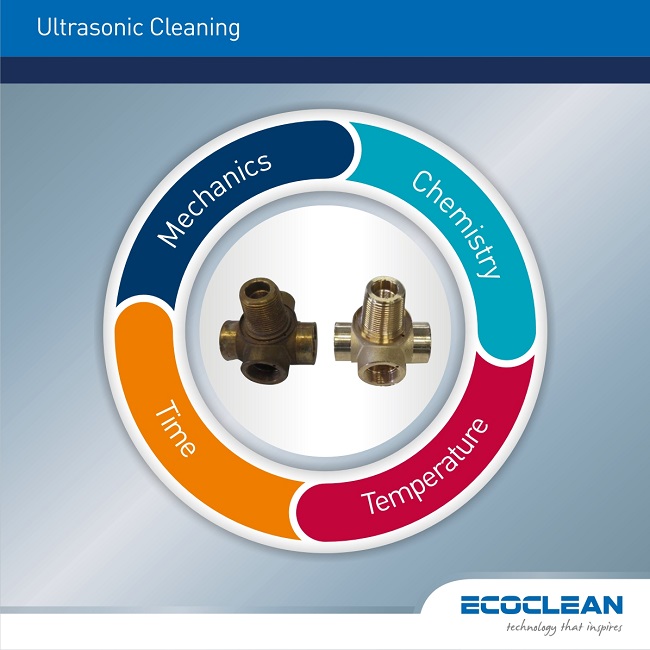

We have seen components, physics, application of various frequencies of Ultrasonic cleaning in our previous articles. The efficacy of the ultrasonic technique depends on multiple parameters such as the balanced combination of cleaning time, media temperature, chemistry and mechanics. Going further, we will see these parameters and limitations of ultrasonic cleaning.

“The ideal ultrasonic cleaning machine allows optimizing the process parameters that can contribute significantly and achieve the desired level of technical cleanliness”

Important Parameters

Optimizing ultrasonic cleaning involves controlling the various standard set of parameters,

- Cleaning Time

- Media Temperature

- Chemistry

- Mechanics

The variation of these parameters impacts the cavitation quality and cavitation effects. We already studied the influence of various range of frequency on the cleanliness result and application of those according to range of particle sizes. Now by adapting the above-mentioned parameters, we can achieve user defined cleanliness results.

What are the limitations of Ultrasonic cleaning?

Now, despite we adapt all these parameters in cleaning tasks, their remains some limitations in this method. In some cases, the limitation occurs due to component properties. For example, the desired cleaning task can not be accomplished on particle generating surfaces of Cast Iron parts when we use ultrasonic treatment alone.

There are few applications where ultrasonic cleaning should not be the only method.

- Parts with difficult geometry, difficult to reach areas

- Particle generating surfaces, e.g. Cast Iron

- Cavitation on sensitive surfaces, e.g. Precious metals

- Parts having blind holes, intersecting galleries

- Bulk parts in perforated metal or plastic boxes

To overcome these limitations, it is therefore recommended to adopt unique approach to assist the mainstream process using ultrasonic cleaning and ensure more efficient cleaning operations. Being the technology expert and worldwide leader in Industrial cleaning market, Ecoclean uses combinations of Injection Flood Wash (IFW) and spray washing together with ultrasonic treatment.

Parts cleaning machines by Ecoclean

Ecoclean offers machines having a variety of processes equipped independently or in combination with each other. These are ranging from spray & immersion cleaning, degreasing, injection flood washing (IFW), high-pressure deburring and ultrasonic cleaning (US) etc.

Our parts cleaning machines demonstrated prominent results when integrated with Ultrasonic cleaning technology. Our carefully built process configuration in Aqueous & Solvent-based machines ensure maximum cleaning quality for various applications across Automotive, E-mobility, Aerospace, Medical Technology, Metal Working and Precision Optics industry.

Ecoclean’s Success Stories

Ecoclean, a worldwide leader in parts cleaning solutions & surface processing, manufactures machines for industrial parts cleaning and surface treatment applications. With extensive experience in the field of industrial parts cleaning technology, Ecoclean, a leading ultrasonic cleaning machines manufacturer in India, helps customers choose the right cleaning machine best suited for a variety of applications. Ecoclean’s success is based on innovation, cutting-edge technology, sustainability and wide reach having locations and technology centres nearer to the customers across the world.

In our next blogs, we will cover some of the Ecoclean’s success stories of the effective implementation of Ultrasonic technology to overcome its limitations. Stay tuned for more updates!

Discover how you can make the most of the latest technology, contact us on info.india@ecoclean-group.net