Table of Contents:

1. Introduction

2. Universal 81W: Economical and Versatile

3. Universal 81C: Degreasing Machines Tailored for Indian Manufacturing

4. Advantages of Ecoclean’s Degreasing Machines

5. Conclusion

FAQs:

The efficient cleaning and degreasing processes in the evolving environment of industrial manufacturing are very important. Ecoclean India is an innovator in industrial component cleaning and surface finishing technology and offers a wide variety of Degreasing Machines to match the stringent requirements of various industries.

Universal 81W: Economical and Versatile

The most prominent product in Ecoclean’s Degreasing Machines line-up is the Universal 81W – a component cleaning machine that can be used on various parts and offers excellent value for money. It possesses a modular design that caters for different kinds of applications, and this solution can be used in various industries ranging from mechanical components to those of aerospace and medical equipment.

Key Features:

- Modular Design: The Universal 81W can be used with different types of materials, including metal, plastic, ceramic or glass components due to its modular design.

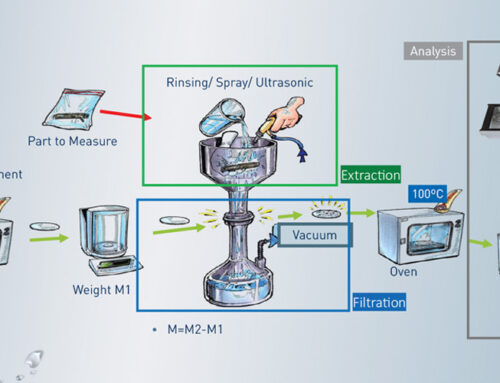

- Multi-Functionality: The machine, which is equipped with features such as spray cleaning, immersion cleaning, ultrasonic cleaning, vapour degreasing and dry clean can guarantee all-round cleanliness application.

- Efficient Cleaning: The use of rotation and oscillation movements, built-in full-flow filtration, oil separator allows cleaning a wide array of mass produced items as well as fine assembly parts to meet the needs.

- Automation: Customisation of process sequences through programming is possible with the Siemens S7 PLC control system, which adds precision and reliability to the processes.

- Optional Extras: Additional optional features that extend the machine’s flexibility include a third flood tank, waste water-free operation, high-power injection flood washing, ultrasonic cleaning unit and vacuum drying.

Universal 81C: Degreasing Machines Tailored for Indian Manufacturing

Seeing the special challenges of Indian markets, Ecoclean presents Universal 81C, a solvent-based parts cleaner that is made in India. This model is designed to meet the requirements of high quality standards needed by modern manufacturing processes, and it offers a variety of hydrocarbon cleaning process alternatives.

Key Features:

- Hydrocarbon Cleaning: The Universal 81C is a hydrocarbon-based solvent, working effectively on oils, greases, emulsions and swarf removal. It offers options for both polar and partially polar solvents.

- Closed Loop Filtration: A two-stage immersion and spray cleaning system with closedloop filtration coupled with highpower injection flood washing ensures effective cleaning alongside efficient solvent disposal.

- Energy Efficiency: The machine has integrated heat recovery technology, making it less consumptive of energy during the cleaning process.

- Safety Features: Multiple-level safety systems, rotation and swivel movements of parts baskets, Siemens S7 PLC control and an advanced interactive HMI make operations safe and reliable.

- Eco-Friendly Operation: The Universal 81C is engineered for emissionless, green operation, indicating its dedication to environmentally friendly practice in industrial activities.

Advantages of Ecoclean’s Degreasing Machines:

- Compact Design: The Universal 81W and Universal 81C have a compact layout with incorporated connection facilities allowing optimal space use in an industrial environment.

- Multi-Step Washing Process: In addition, hot-air and vacuum drying in washing can also guarantee complete cleaning and effective drying leading to higher component quality.

- Waste Water-Free Operation: The ability to operate with no waste water and an included treatment unit for freshwater, Aqua-clean, contributes towards sustainable manufacturing practices.

- Stainless Steel Construction: All contact parts made of stainless steel ensure its service life and resistance to corrosion by cleaning media.

- Modular Design for Upgrades: Both machines feature a modular design allowing for upgrades, offering flexibility in future improvements and adjustments due to changes within the industry.

In summary, the manufacturing units of Ecoclean are the beacons of efficiency and reliability in the industrial cleaning world. These machines, outlining simplicity, flexibility, and environmental responsibility provide a pragmatic approach to various cleaning needs in different industries helping operate modern manufacturing processes smoothly.

FAQs:

1. What industries can benefit from Ecoclean’s Degreasing Machines?

– Answer: Ecoclean’s equipment caters to a wide range of industries, from mechanical components to aerospace and medical equipment.

2. What is the significance of the modular design in the Universal 81W?

– Answer: The modular design allows the Universal 81W to handle different materials, making it versatile for various applications.

3. How does the Universal 81C address the challenges of the Indian market?

– Answer: The Universal 81C is specifically tailored for Indian manufacturing, meeting the high-quality standards required by modern processes.

4. What cleaning processes are available in the Universal 81W?

– Answer: The Universal 81W offers spray cleaning, immersion cleaning, ultrasonic cleaning, vapour degreasing, and dry cleaning.

5. How does the Universal 81C contribute to energy efficiency?

– Answer: The machine incorporates heat recovery technology, reducing energy consumption during the cleaning process.

6. Can the Universal 81W be customized for specific cleaning requirements?

– Answer: Yes, the Siemens S7 PLC control system allows custom programming for precise and reliable cleaning processes.

7. What safety features are integrated into the Universal 81C?

– Answer: The machine features multiple safety systems, rotation and swivel movements of parts baskets, and advanced interactive HMI for safe operations.

8. How does Ecoclean ensure eco-friendly operation with the Universal 81C?

– Answer: The Universal 81C is engineered for emission-free, environmentally friendly operation, aligning with sustainable manufacturing practices.

9. Are there options for additional features in Ecoclean’s Degreasing Machines?

– Answer: Yes, optional extras include a third flood tank, waste water-free operation, high-power injection flood washing, ultrasonic cleaning unit, and vacuum drying.

10. Can the Universal 81W and Universal 81C be upgraded for future improvements?

– Answer: Both machines feature a modular design that allows for upgrades, providing flexibility for future enhancements and adjustments to industry changes.