In the fast-paced world of manufacturing, efficiency is king. Every minute counts and any disruption to your production line can translate to lost revenue and frustrated customers. Grease, oil, and grime are an inevitable reality in many manufacturing processes. But what if there was a way to tackle these contaminants quickly, effectively, and without hindering your production flow? Enter degreasing machines – the unsung heroes of a smooth-running production line.

Degreasing machines are industrial cleaning systems designed to remove grease, oil, and other contaminants from parts, tools, and machinery. They come in various configurations – from small, manual units to large, automated systems – catering to a wide range of cleaning needs. Here’s how degreasing machines can transform your production line:

- Enhanced Efficiency: Manual degreasing can be a time-consuming and laborious process. Degreasing machines automate a significant portion of the cleaning, freeing up your workforce to focus on higher-value tasks. This translates to increased output and a more efficient production cycle.

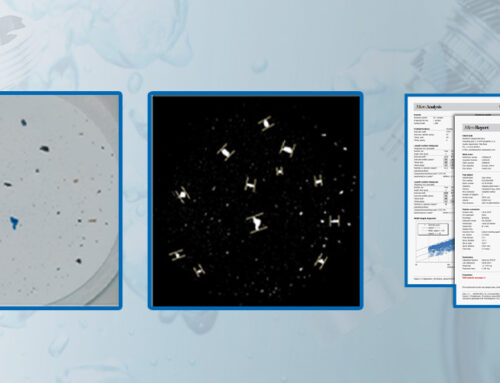

- Improved Quality Control: Degreasing ensures parts are thoroughly cleaned before further processing or assembly. This eliminates the risk of contaminants affecting product quality or causing adhesion issues with paints, coatings, or adhesives.

- Reduced Downtime: Inefficient cleaning methods can lead to clogged machinery and equipment failures, resulting in costly downtime. Degreasing machines ensure consistent and thorough cleaning, reducing the risk of breakdowns and keeping your production line running smoothly.

- Safety First: Manual degreasing often involves harsh chemicals and solvents, posing safety risks to workers. Degreasing machines often use closed-loop systems and eco-friendly cleaning solutions, minimizing exposure to hazardous materials.

- Environmental Responsibility: Traditional degreasing methods can generate hazardous waste. Modern degreasing machines incorporate features like oil skimming and filtration systems, allowing for cleaner operation and responsible waste disposal.

Choosing the Right Degreasing Machine for Your Needs

With the diverse range of degreasing machines available, selecting the right one for your production line is crucial. Here are some key factors to consider:

- Part Size and Volume: The size and capacity of the machine should accommodate the parts you need to clean and the cleaning volume required.

- Contaminant Type: Different degreasing solutions are effective for various types of grease, oil, and grime. Consider the specific contaminants you need to remove.

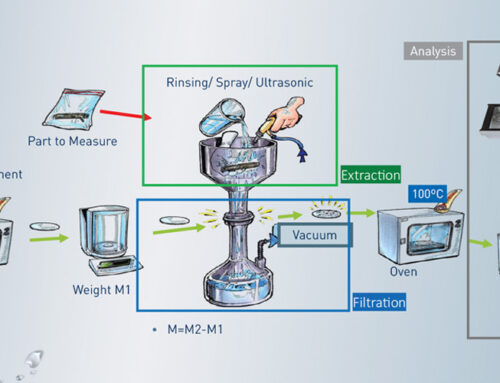

- Cleaning Process: Choose a machine with a cleaning process that aligns with your production flow. Options include immersion, spray, or ultrasonic cleaning.

- Automation Level: Manual, semi-automatic, or fully automatic machines cater to different needs. Consider your workforce availability and desired production speed.

- Environmental Regulations: Ensure the machine complies with environmental regulations regarding waste disposal and solvent usage.

Ecoclean India: Your Partner in Degreasing Solutions

At Ecoclean India, we understand the importance of efficient and effective cleaning in your production process. We offer a comprehensive range of degreasing machines, from compact benchtop models to high-capacity industrial systems.

Our team of experts will help you select the right machine for your specific needs and ensure it seamlessly integrates with your existing production line. We also offer after-sales support and maintenance services to keep your degreasing machine functioning optimally for years to come.

Investing in a degreasing machine from Ecoclean India is an investment in the transformation of your production line. Experience increased efficiency, improved quality control, and a safer work environment. Contact us today to discuss your degreasing needs and discover how our machines can help you achieve a cleaner, more productive future.