Our SBS Ecoclean Group possesses a wealth of knowledge about cleaning technologies, future innovations and sustainable industry solutions. So, how do we keep developing new ideas and products? By being curious, exchanging knowledge and teaming up with other experts in the field.

Over the last couple of years, we have found a number of great new ways to communicate digitally. But of course, this will never fully replace the feeling of coming together and talking about our passions face to face. While some regions were still affected by lockdowns and restrictions this year, we have enjoyed meeting our colleagues and customers in person wherever possible.

- We met at numerous trade shows. In total, we participated in 39 events around the world, including in Paris, Istanbul, Bangkok and Chicago, where we got the chance to present new products, hold webinars and build

- We held exclusive customer events. In March, for example, we invited Moog Inc. employees to our new Test Center in Alcester, UK, where they learned more about Ecoclean’s industrial cleaning technology. While the visitors had the chance to see our machines in operation, they were also invited to bring along some components for cleaning tests.

- We welcomed strong new partner companies to our global sales network and were able to visit business partners again. In cooperation with Forplan AG and STS Industrie SA, the SBS Ecoclean Group is extending its range of turnkey solutions for the Medical Industry. The Johan Nordström Verktygsmaskiner AB has entered our European sales network and is supporting us with its local expertise and market know-how in Sweden and In Italy, our Sales colleagues visited SCS Impianti S.r.l. – our After-Sales Service Representative for Italy. And the list goes on!

- We opened new Technology Centers that help us develop and test the best cleaning processes for you. New high-tech centers were opened in Turkey, the UK and Germany, with each specializing in different cleaning Furthermore, a brand new EcoCcore solvent cleaning machine for cleaning trials using originally contaminated parts from customers’ production is now available in Bursa, Turkey.

We are happy to have met so many of you again in person this year and talk about innovation – particularly in special cleaning solutions. We cannot wait to see you again in 2023!

Meeting new cleaning standards for demanding High Purity components

This year, more than ever before, the trends in the cleaning industry are shifting towards precision cleaning and High

Purity cleaning systems. “We have been noticing a strong development potential in the High Purity sector. We are adapting cleaning processes, control software, machinery and ambient conditions to the evolving requirements and applications seen in the semiconductor industry, optics and high-tech industry,” explains Rainer Straub, VP Sales & Customer Service from our Center of Competence in Filderstadt, Germany.

Complex requirements

In such industries Straub mentions, there is a trend towards the use of components with a wide variety of materials and increasing complexity. Besides the demand for outstanding performance and reliability, modern High Purity cleaning systems must:

- be suitable for heavy and large, but also small and complex, workpieces

- be adaptable to a broad range of materials

- meet medical specifications regarding particulate, film-type-chemical, organic and inorganic cleanliness

- take into account complex geometries and modified materials

- meet outgassing rates for organic substances and residual moisture, as well as limit values down to the atomic percent range when it comes to surface analyses for residues of prohibited substances/elements

- achieve exceptionally clean surfaces required for high-tech coating technology

Extension of High Purity portfolio

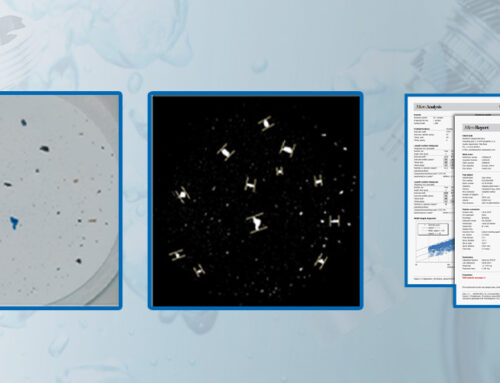

Our answer is a whole High Purity product family comprising products designed especially for precision and multi- chamber cleaning, new UCM-Products (UCMSmartLine, UCMPerformanceLine), customized solutions as well as Ecoclean High Purity Products, including special solvent and aqueous chamber cleaning machines and features like the Pulsated Pressure Cleaning techniques (PPC). At this year’s industry events, we have globally showcased multiple innovations related to High Purity applications. For example, at the parts2clean show in Germany, we unveiled the new EcoCcompact High Purity cleaning system, which is validated for Grade 2 cleaning of High Purity components. In addition to new products, the Ecoclean Center of Competence in Filderstadt, Germany has opened a test center dedicated to High Purity solutions.

New High Purity Technology Center in Germany

Our new High Purity Technology Center in Germany is equipped with the latest technology and offers lots of opportunities for analysis. It allows us to run cleaning trials with original parts, simulating real production conditions to find the right solution to your cleanliness requirements. All relevant process parameters can be monitored, documented and transferred to higher-level systems. With special High Purity cleanrooms and the appropriate analysis equipment, we can also optimize processes and determine part-specific cleaning parameters for the best possible outcome.

Systematic process analysis: optimizing with a holistic approach

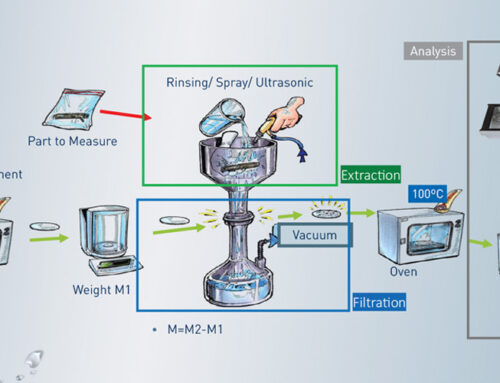

When it comes to making parts cleaning operations more reliable, economical, and sustainable, the first step to optimization is a systematic process analysis.

There are usually two reasons for a thorough analysis: either cleaning problems are occurring, or the customer seeks modernization. In both cases, our specialists define the problem and goal and put factors like rinse water quality, bath treatment, process technology and sequence to the test. In the event of cleaning problems, it is important to not stop after an error-free result. To prevent further recontamination or corrosion, handling, transport or packaging must be

considered as well. Where modernization is the desired outcome, a cleaning procedure can be a huge game changer with regard to time savings, cost efficiency and sustainability. Potential areas for optimization are identified via an in- depth analysis of the cleaning process. The systematic process analysis allows us to take a look at the bigger picture.

Identifying sources of error

Particles, stains or filmic residues on parts after cleaning count as unsatisfactory results and can cause a much longer and therefore more energy-intensive cleaning process. Sources of error are manifold and can include the wrong choice of cleaning containers, a clogged filter or residual particles in the working chamber.

Following our holistic approach

The analysis focuses on the actual cleaning process and equipment, and the overall manufacturing environment. Because it is not only the process and related technology that play a part in cleanliness; other factors surrounding the process also have an influence. A holistic, 360-degree approach is needed to define the problem, determine the potential for optimization and restore the high-standard and reliable quality of the final product.

Expertise is key

Qualified personnel play a decisive role in the process analysis and the implementation of optimization measures. To make optimum use of a cleaning system, ensure the required cleaning quality, and for the system to work economically and environmentally friendly, extensive know-how is essential. This is why we believe that investing in the training and continuing education of cleaning staff is a cornerstone of achieving reliable cleanliness. So, the Ecoclean Academy offers a combination of process analysis with conventional training courses.

Parts cleanliness is essential to the quality of a product. The systematic process analysis can help restore an insufficient cleaning process by identifying the sources of errors as well as any retrofitting and upgrading requirements in the cleaning system.

More information

To learn more about our systematic process analysis, visit our Academy or contact our process analysis experts: academy.filderstadt@ecoclean-group.net

Award-worthy: Ecoclean’s solution for energy-efficient production

Climate change, energy transition and the need to conserve resources make saving energy a hot topic right now. Climate neutrality and the transformation of industry are key areas of focus that have been occupying us for years and for which we can already offer comprehensive solutions. We want to make existing production plants more energy efficient and

sustainable. This is the purpose of the Ecoclean’s Dynamic

Flow Control (DFC) – our established solution for energy saving

– which was nominated for the Energy Efficiency Award 2022.

The Ecoclean DFC: delivering the exact volume required

Cooling water circuits and cooling towers, heating and ventilation systems, water supply systems – all of these technologies, which deliver varying quantities of liquid and gaseous substances, offer huge potential for energy savings. Ecoclean has harnessed this potential with its dynamic volumetric flow controller, which makes it possible to control the pumps, so they deliver the exact volume required.

The Ecoclean DFC uses measuring sensors that are integrated into the main outlet of the processing system. In combination with variable frequency drive units for the pumps, this allows the pump speed to be controlled so precisely that the amount of coolant delivered is automatically adapted to the current fluid requirement. The control is based on the measured variables of pressure and volumetric flow rate. It enables energy savings of more than 80 GWh, mean cost savings of more than 34 percent and less than two years of amortization.

Great recognition for our product

Ecoclean was nominated for the Energy Efficiency Award 2022 for its innovative volumetric flow controller. We were shortlisted among approximately 130 other projects and concepts submitted.

The focus of the award is on projects that generate energy and CO2 savings, as well as concepts that show how climate neutrality and industry transformation can succeed. Conferred by dena – the German Energy Agency – the award honors projects that increase energy efficiency and reduce greenhouse gases. We were nominated in the category “From clever to digital: The broad spectrum of energy efficiency”.

“It is such an honor for us to be nominated for the Energy Efficiency Award 2022 and be recognized for a project that helps our customers reduce energy waste and costs. We meet exactly the need of manufactures by offering a solution which protects the climate and also allows cost savings,” says Jochen Theissen, Senior Manager Customer Service at our Center of Competence in Monschau, proudly.

More information

To learn more about our solution for energy efficiency, visit our website and contact our Ecoclean DFC experts: service.monschau@ecoclean-group.net