In today's competitive manufacturing landscape, ensuring the cleanliness of components is more critical than ever. Whether you're in the automotive, aerospace, or medical device industry, having a streamlined cleanliness inspection workflow can significantly enhance quality control, reduce production delays, and ensure compliance with international standards like ISO 16232 and VDA 19.

- Understanding the Cleanliness Inspection Process

The cleanliness inspection process involves three key stages: extraction, filtration, and analysis. Each stage plays a crucial role in determining the cleanliness level of a component by identifying and quantifying the residual particles within threshold limit. .

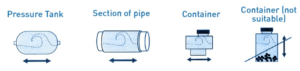

- Extraction: The process begins with the extraction of particles from the test component using various methods such aspressure rinsing, ultrasonic cleaning, and internal rinsing.

- Filtration: After extraction, the particles are filtered out on a membrane for further measurement and analysis.

- Analysis: The final stage involves analyzing the extracted particles to determine their weight, type, size, and quantity. Techniques likegravimetry, light optical analysisare commonly used in this stage.

- Selecting the Right Extraction Method

Choosing the appropriate extraction method is essential for obtaining reliable results. Depending on the type of contamination and component material, you might use one or a combination of these methods:

Pressure Rinsing:

- Ideal for large surfaces and bulk parts. This method uses a high-pressure nozzle to dislodge particles. Key parameters to control include nozzle type, diameter, pressure, volume flow, and time.

Ultrasonic:

- Suitable for parts that has complex geometry and difficult to reach areas. . Parameters like ultrasonic frequency, tank volume etc.are crucial for achieving optimal cleaning results.Internal Rinsing:

- Used for cleaning internal passages, such as tubes or oil holes. This method involves controlling parameters like pressure, flow rate, pulsation, and reversal of direction.Extraction by Agitation:

- Agitation extraction uses mechanical means such as stirring or shaking in a solvent to dislodge and suspend contaminants from the component's surface. Key parameters to control are filled volume, amplitude, frequence and time.Each of these methods has its own set ofadvantages and limitations, and selecting the right one depends on the specific requirements of the component and the type of contamination.

- Optimizing Filtration Techniques

- Once the particles have been extracted, they must be effectively filtered on a membrane or filter paper for analysis. Proper filter preparation is critical to obtaining accurate results. Key considerations include:

- Filter Type and Preparation: The filter preparation process, especially with a filter cascade, is crucial for effectively quantifying and characterizing particles in the cleaning process. Depending on the particle size and analysis type, different filters with different pore size (Example 8 micron, 15 micron etc.). such as cellulose nitrate or PET mesh filters, may be used.

- Particle Accumulation:Larger particles accumulate on the coarse filter, while smaller particles are captured on subsequent finer filters

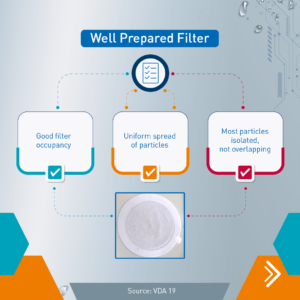

- Well Prepared Filter:A well-prepared filter is essential for accurate cleanliness testing. Ensure the filter is free from contaminants and adequately prepared to retain particles without introducing new ones.

Avoiding Common Filtration Errors:

- Overloaded filters or particles along the edges can skew results. Remedies like using fewer parts per filter, adjusting suction pressure, or optimizing the filter holder can help prevent these errors. For more details on common errors and remedies, refer to ourcomprehensive guide.Achieving a well-prepared filter with good occupancy, uniform particle spread, and isolated particles is vital for effective cleanliness testing. Following best practices ensures reliable results, facilitating accurate assessment of component cleanliness and compliance with industry standards.

- Streamlining the Analysis Phase

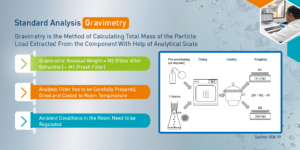

- The analysis phase is where the extracted and filtered particles are assessed to determine their size, type, and quantity. Several methods including Millipore Test and Gravimetry Test are widely used methods in the evaluation of component cleanliness, particularly in industrial applications.

- Gravimetry Test: Measures the total mass of extracted particles using an analytical scale. Gravimetric analysis requires precise filter preparation and control over ambient conditions to ensure accuracy.

- Millipore Test: The Millipore Test is performed to assess the cleanliness of components by measuring the amount of particulate contamination present in the extracted fluid.

- Light Optical Analysis: A cost-effective method that uses light microscopy to analyze particles. It is fast, easy to use, and suitable for both routine and extended analysis.

- Advanced Techniques: Methods likeSEM-EDX, Raman Spectroscopy, and LIBSoffer in-depth particle characterization for complex contamination scenarios.

To improve efficiency, consider using automated solutions like theMicroQuick scanner, which has been recognized in international norms such as VDA-19.1 and ISO-16232 for its speed and reliability.

- Automating the Reporting Process

- A streamlined cleanliness inspection workflow doesn't end with the analysis; generating and sharing reports quickly and accurately is equally important. Here are some tips for efficient reporting:

- Automated Report Generation: Use tools that integrate directly with your analysis equipment to automatically generate reports in a standardized format, such as Microsoft Excel or PDF. This reduces manual entry errors and saves time.

- Clear and Concise Reporting: Ensure your reports are easy to understand by including clear visual aids like particle galleries and charts. Use color-coded ratings (green, yellow, red) to highlight critical areas that need attention.

- Audit Readiness: Regularly update your report templates and auditing procedures to comply with the latest standards. Automated calibration features,, help maintain consistency and accuracy over time.

- Key Takeaways for Streamlining Your Workflow

By adopting a streamlined cleanliness inspection workflow, you can:

- Enhance Efficiency: Reduce inspection time by selecting the right extraction and analysis methods.

- Improve Accuracy: Optimize filtration and analysis techniques to minimize errors.

- Ensure Compliance: Stay up-to-date with international standards like ISO 16232 and VDA 19.

- Facilitate Reporting: Use automated tools and clear reporting formats to simplify communication and auditing.

Conclusion

Streamlining your cleanliness inspection workflow from testing to reporting can significantly improve the quality and efficiency of your operations. By carefully selecting the right methods, optimizing filtration, and leveraging advanced analysis techniques, you can ensure that your components meet the highest cleanliness standards.

To learn more about our range ofcleanliness inspection solutionsand how we can help you achieve your quality goals, visit our website today.