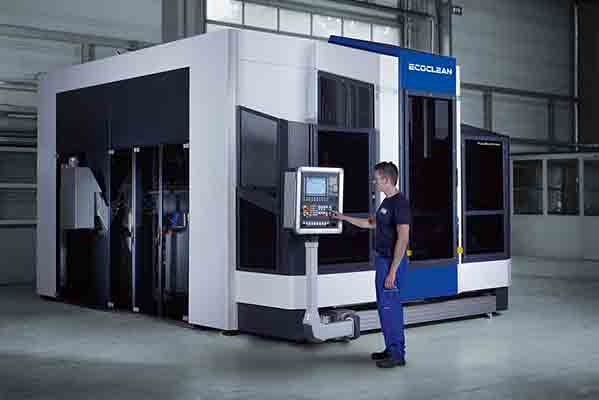

PulseBoreCenter – Surface processing with EcoCbooster technology

The PulseBoreCenter makes use of Ecoclean’s EcoCbooster system to activate and de-coat cylinder liners by a medium-pressure technique. By contrast, the high-pressure water jetting methods formerly employed for surface activation operated in the ultra-high pressure range. The significant reduction in pressure is achieved thanks to the pulsating water jet principle which provides a substantial increase in kinetic energy and thus improved surface activation for unsurpassed adhesive strength.

We provide both the Particle Scanner and the cleanliness analysis service which is required for determining the technical cleanliness of the components in accordance with inspection standards ISO 16232 and VDA 19.

Related Products

UCMCombiLine

Cleaning of small-sized parts efficiently - across all industries

EcoCvelox

High-pressure waterjet deburring efficiently combined with low-pressure cleaning processes

PulseBoreCenter

Surface processing with EcoCbooster technology

EcoCbooster

For innovative surface processing based on pulsation technology

EcoCdry

Highly efficient vacuum dryer for the special drying of scooping components

EcoCduty

The large-chamber cleaning system for superior cost efficiency