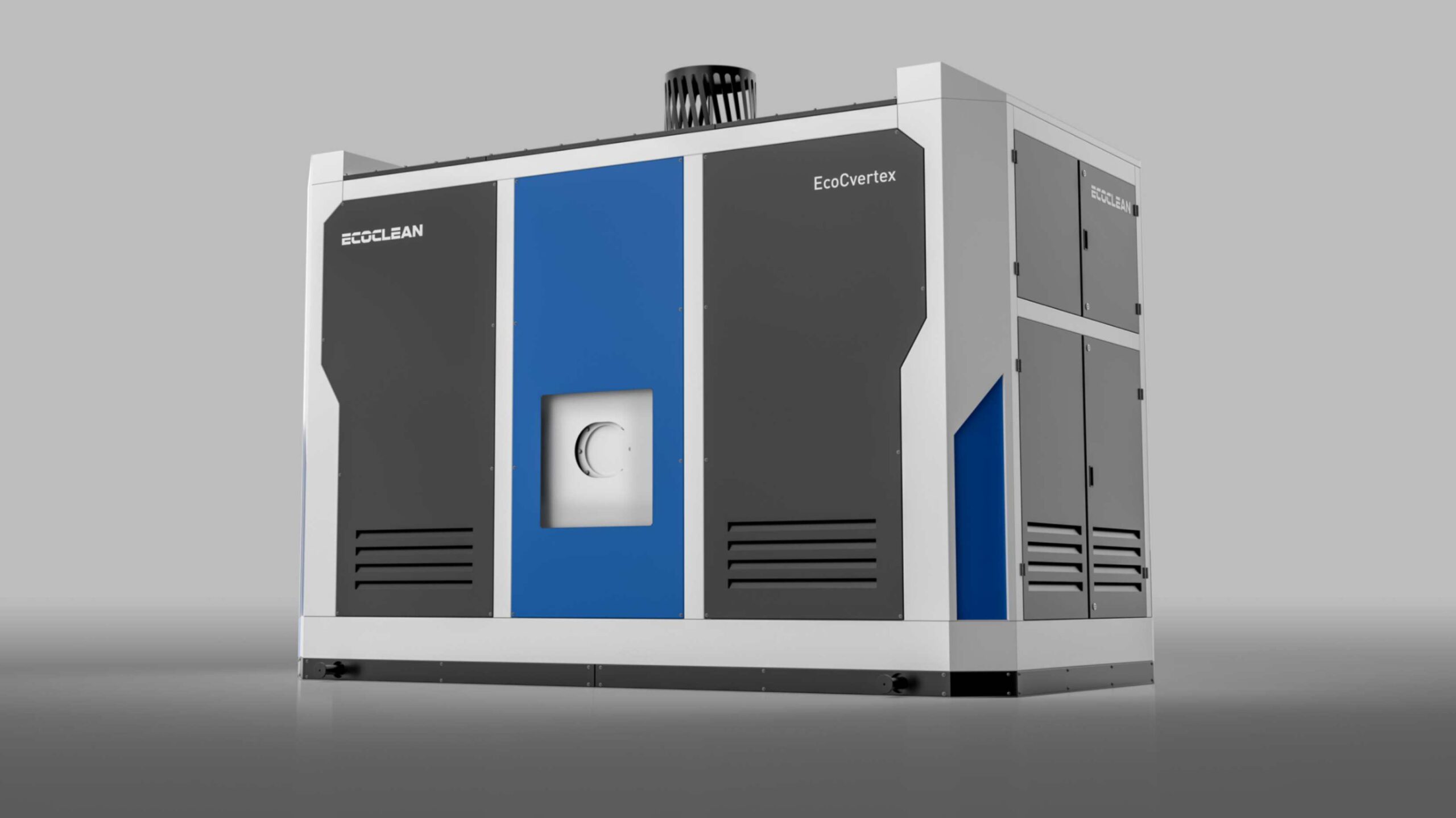

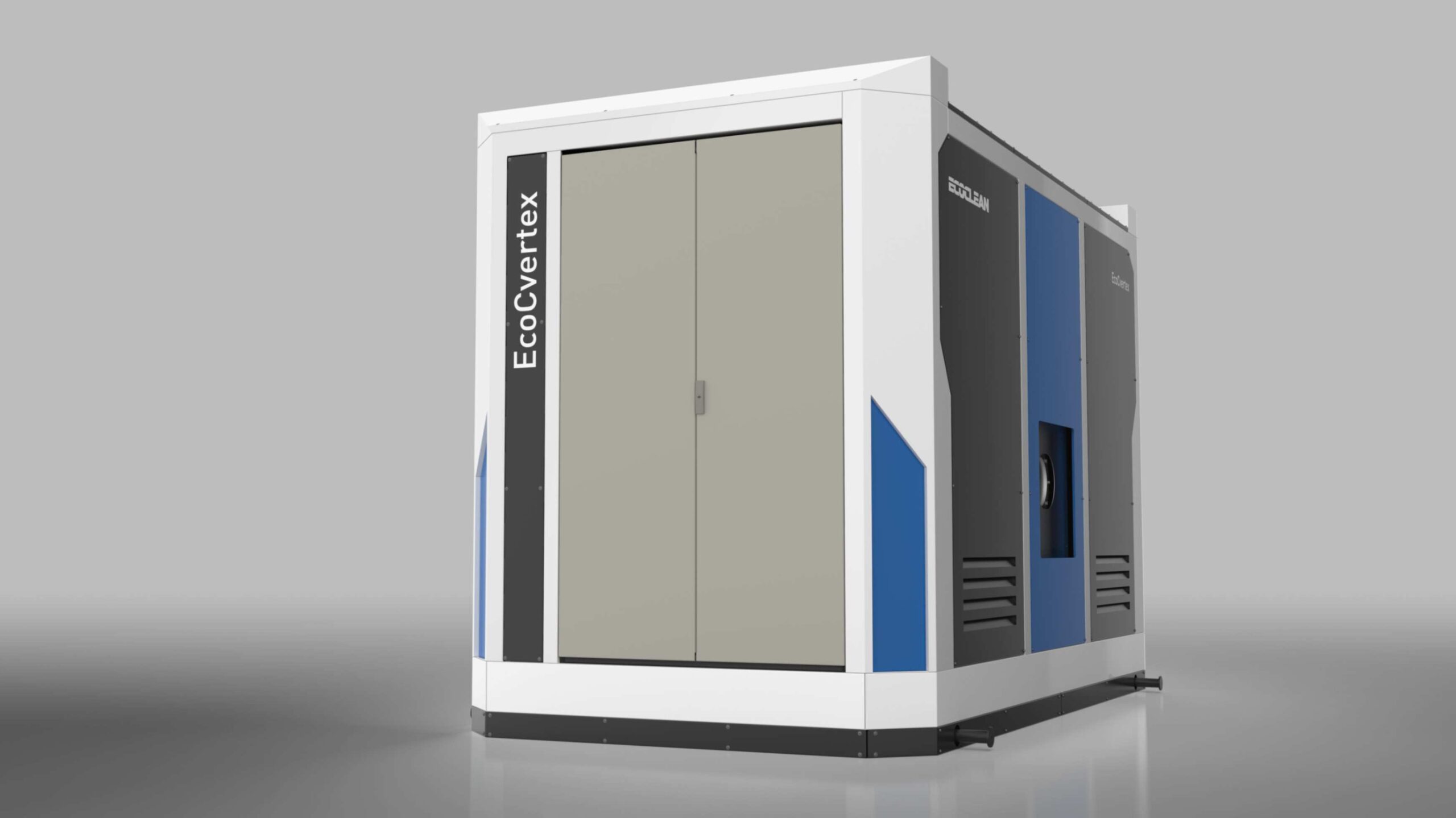

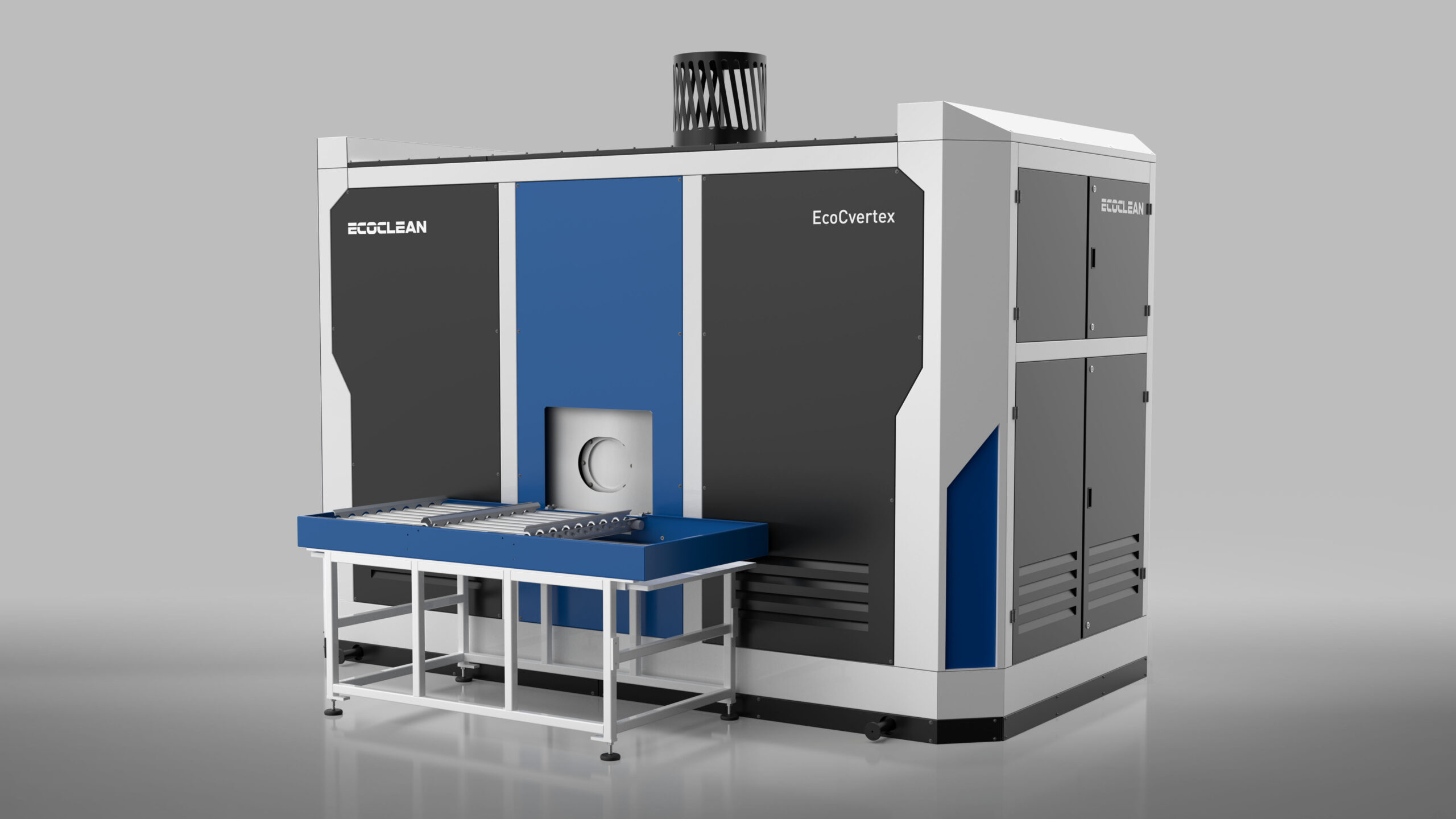

EcoCvertex – Elevating Standards, Maximizing Efficiency

The EcoCvertex machine is a state-of-the-art aqueous-based cleaning system designed to elevate industrial cleaning standards while maximizing operational efficiency.

Built with upright cylindrical 3rd tank, which have been developed for fine cleaning applications, ensures optimized fluid management. With optional 4th flood tank, it delivers unparalleled flexibility for diverse cleaning needs, including spray cleaning, high-power injection flood washing, and ultrasonic cleaning.

Its compact footprint ensures optimal space utilization without compromising maintenance accessibility, while advanced filtration systems and integrated oil separators enhance fluid management and minimize cross-contamination. Equipped with latest PLC controls and an interactive HMI, the EcoCvertex offers precise process customization and real-time monitoring, making it both user-friendly and highly efficient.

Related Products

UCMCombiLine

Cleaning of small-sized parts efficiently - across all industries

EcoCvelox

High-pressure waterjet deburring efficiently combined with low-pressure cleaning processes

PulseBoreCenter

Surface processing with EcoCbooster technology

EcoCbooster

For innovative surface processing based on pulsation technology

EcoCdry

Highly efficient vacuum dryer for the special drying of scooping components

EcoCduty

The large-chamber cleaning system for superior cost efficiency