After pre-cleaning is completed, the next important step in the manufacturing of medical implants and instruments is Intermediate Cleaning. This stage comes after machining and before final cleaning, and it plays a major role in removing residues left from polishing, grinding, passivation, and coating processes.

If these residues are not removed properly, they can affect the success of surface treatments like passivation and coating. They can also reduce the performance, safety, and life of the medical product.

Purpose of Intermediate Cleaning

During the manufacturing process, different operations introduce new types of contaminants. Intermediate cleaning is done to remove these specific residues, which include:

- Polishing paste

- Grinding dust

- Abrasive particles

- Organic and inorganic dirt

- Chemical residues (from passivation and coating)

This stage ensures the parts are clean and prepared for final processes such as coating, sterilization, and packaging.

Where Does Intermediate Cleaning Fit in the Process?

Intermediate cleaning is typically required after surface processing steps, such as:

- Polishing – Leaves behind polishing paste and dust

- Grinding – Produces fine abrasive particles, grinding dust

- Passivation – Leaves traces of nitric or citric acid, organic/inorganic contamination

- Coating –Organic/inorganic particles, Coating particles and dust

All of these steps can add layers of contaminants that must be removed before the part moves to final cleaning or inspection.

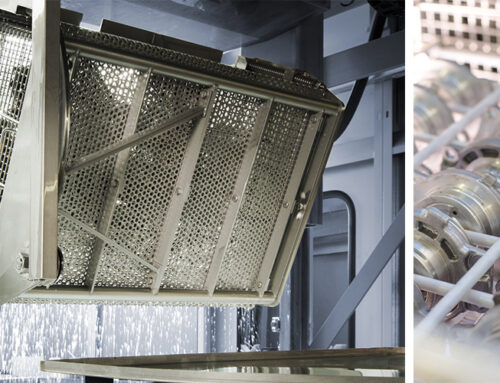

Cleaning Methods Used in Intermediate Cleaning

Ecoclean offers advanced aqueous-based cleaning solutions for this stage. These machines are equipped to handle the removal of both physical and chemical contaminants using processes like:

- Immersion cleaning with agitation

- Ultrasonic cleaning for fine particle removal

- DI water rinsing to maintain high purity

- Vacuum or hot air drying to prevent recontamination

Cleaning recipes can be customised based on the part’s material, contamination level, and surface finish.

Recommended Machines for Intermediate Cleaning

All machines used at this stage are aqueous-based, as water-based cleaning is highly effective and sustainable for removing polishing and passivation residues.

Suitable Machines:

- Universal 81W

- EcoCmini

- UCMCombiLine

- UCMBaseLine

These machines support modular configurations and can be adapted to your production volume, cleanliness requirements, and part geometry.

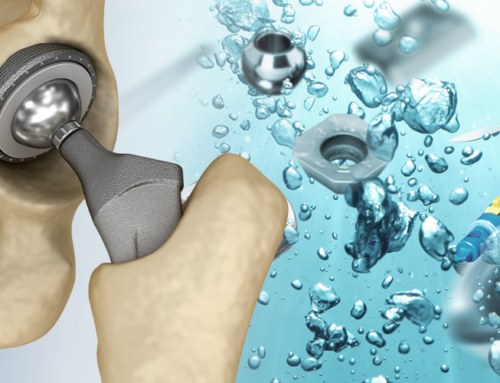

Typical Parts Cleaned at Intermediate Stage

Intermediate cleaning is used for a variety of parts, including:

- Orthopaedic implants (hip, knee, trauma, cranial)

- Dental and orthodontic implants

- Surgical tools and instruments

- Rotating ENT and neuro instruments

- Arthroscopic shaver blades

- Coated components requiring surface finish integrity

Conclusion

Intermediate cleaning may sit between pre-cleaning and final cleaning, but it is just as essential. By ensuring all surface residues are removed properly, it helps in delivering safe, clean, and compliant medical devices that meet global standards.

Want to Upgrade Your Intermediate Cleaning Process?

At Ecoclean, we offer modular and automated cleaning solutions designed specifically for medical manufacturers. Whether you need to clean after passivation, polishing or coating — we can help you select the right machine setup to meet your cleanliness, throughput, and validation needs.

Stay tuned for our next blog where we’ll cover Final Cleaning & Packaging — the last step before your medical parts go for sterilization.

Need help today? Reach out to our experts at info.india@ecoclean-group.net and let’s find the best solution for your medical cleaning needs.