Ultrasonic cleaning technology has revolutionized the cleaning industry, offering a safe, efficient, and precise method for removing contaminants from various Industrial component.Traditionally used in the jewelry and medical sectors, ultrasonic cleaning is now finding its way into a wider range of applications due to its unique capabilities.

What is Ultrasonic Cleaning?

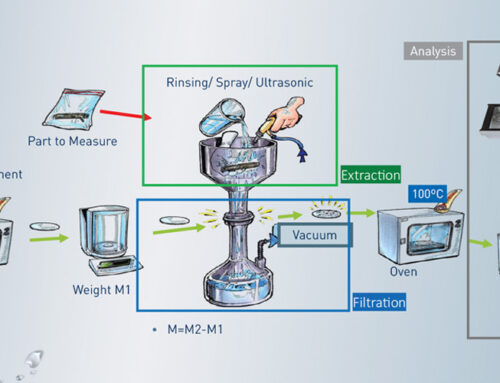

Ultrasonic cleaning utilizes high-frequency sound waves above the audible range (ranging from 25 kHz to 40 kHz) to create microscopic Cavitation within a cleaning fluid. These cavitation rapidly expand and collapse, generating a scrubbing action that dislodges dirt, grease, and other contaminants from the immersed object’s surface and even microscopic crevices.

Advantages of Ultrasonic Cleaning

Ultrasonic cleaning offers several advantages over traditional cleaning methods:

- Gentle Yet Effective:Unlike abrasive cleaning techniques that can damage delicate surfaces, ultrasonic cleaning is incredibly gentle. This makes it ideal for cleaning intricate parts, sensitive electronics, and medical implants

- Thorough Cleaning:The cavitation process reaches even the blind holes and intersecting galleries nsuring a deep and thorough clean that traditional methods might miss.

- Efficiency:Ultrasonic cleaning can significantly reduce cleaning time compared to manual methods.

- Environmentally Friendly:Ultrasonic cleaning often eliminates the need for harsh chemicals, making it a more environmentally friendly cleaning solution.

Innovative Applications of Ultrasonic Cleaning Technology

Beyond its traditional uses in jewelry and medical device cleaning, ultrasonic cleaning is making waves in various industries due to its unique benefits. Here are some innovative applications:

- Aerospace and Aviation:Ultrasonic cleaning is crucial for maintaining the delicate components of aircraft engines and other aerospace parts. It removes contaminants that could compromise performance and safety.

- Automotive Industry:From fuel injectors and carburettors to car parts and sensors, ultrasonic cleaning plays a vital role in ensuring the smooth operation and longevity of vehicles.

- Electronics Manufacturing:Ultrasonic cleaning is essential for cleaning circuit boards, removing solder paste residue, and ensuring the flawless functioning of electronic devices.

- Medical Devices:Surgical instruments, implants, and other medical equipment require a high degree of cleanliness to prevent infections. Ultrasonic cleaning provides a safe and effective method for Precision cleaning of these applications.these instruments.

- Optical Industry:Ultrasonic cleaning is used to clean lenses, mirrors, and other optical components without damaging their delicate surfaces, ensuring optimal performance.

The Future of Ultrasonic Cleaning Technology

The future of ultrasonic cleaning technology is bright, with ongoing research and development leading to even more innovative applications. Here are some exciting possibilities:

- Nanoparticle Cleaning:Ultrasonic cleaning could be adapted to clean objects at the nanoscale, such as microchips and other nanotechnologies.

Conclusion

Ultrasonic cleaning technology is a powerful tool that offers a multitude of benefits for various industries. As research and development continue, we can expect even more innovative applications of this versatile technology in the years to come.

Ecoclean India: Your Partner in Ultrasonic Cleaning Solutions

At Ecoclean India, we are committed to providing cutting-edge ultrasonic cleaning solutions for various industries. We offer a wide range of ultrasonic cleaning machines designed to meet the specific needs of our clients.

Our team of experts can help you choose the right ultrasonic cleaning machine for your application and ensure you get the most out of this powerful technology.

Contact Ecoclean India today to discuss your ultrasonic cleaning requirements.