Summary

Modern manufacturing demands consistent, measurable, and process-stable component cleanliness. The EcoCvertex industrial cleaning machine is engineered to address these requirements by integrating cleaning, rinsing, and drying into a single, controlled process. This pillar blog explains how EcoCvertex functions as an aqueous-based cleaning solution, the manufacturing challenges it solves, its technical capabilities, and why it is a strategic investment for quality-driven production environments.

Table of Contents

- Introduction

- Why Industrial Parts Cleaning Requires Process-Controlled Machines

- EcoCvertex Designed as a Manufacturing Process Solution

- Technical Architecture of the EcoCvertex Cleaning System

- How EcoCvertex Ensures Repeatable Cleaning Results

- Application Areas Where EcoCvertex Delivers Value

- EcoCvertex vs Conventional Cleaning Systems

- Key Benefits for Modern Manufacturing Plants

- Conclusion

- Frequently Asked Questions

Introduction

In today’s manufacturing landscape, industrial parts cleaning has evolved into a defined process requirement. Increasing component complexity, tighter tolerances, and higher cleanliness standards demand machines that can deliver consistent results under controlled conditions.

The EcoCvertex industrial cleaning machine is developed to function as a process-integrated solution, supporting manufacturers who require stable, repeatable, and auditable cleaning outcomes across diverse production environments.

Why Industrial Parts Cleaning Requires Process-Controlled Machines

Manufacturing operations such as machining, grinding, and forming introduce contaminants including oils, fine particles, and residual films. If these contaminants are not removed in a controlled manner, they can affect:

- Assembly accuracy

- Functional performance

- Surface quality

- Long-term component reliability

Manual or loosely controlled cleaning methods often introduce variability. Process-controlled machines like EcoCvertex eliminate this variability by stabilizing key cleaning parameters.

EcoCvertex Designed as a Manufacturing Process Solution

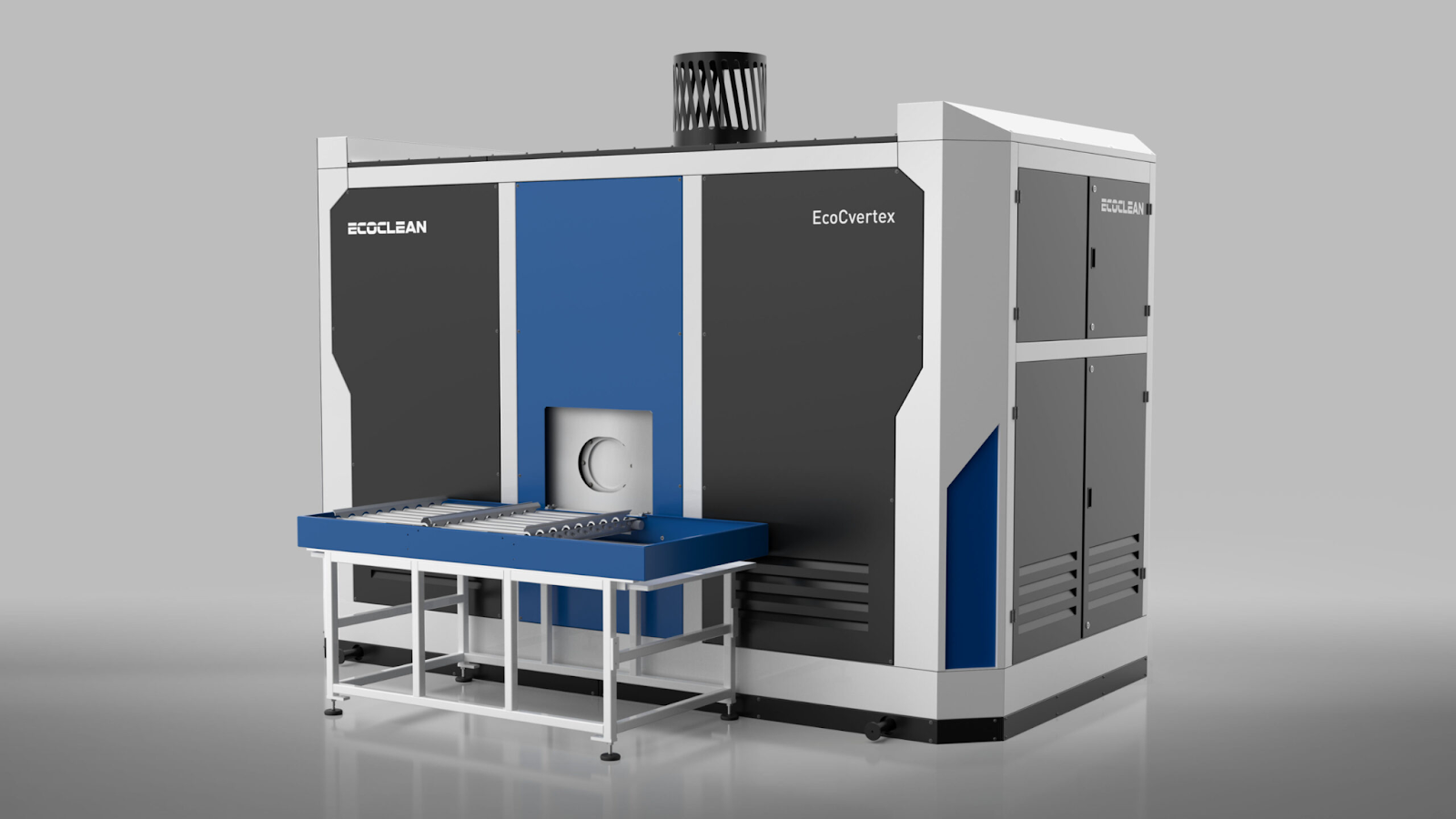

EcoCvertex is engineered as a single-chamber, multi-process industrial cleaning machine. Instead of treating cleaning as a separate operation, it integrates multiple stages into one controlled environment.

The system manages:

- Mechanical cleaning energy

- Temperature stability

- Media filtration and circulation

- Defined cycle times

- Controlled drying performance

This integrated design ensures repeatable cleanliness results, independent of operator influence.

Technical Architecture of the EcoCvertex Cleaning System

Single-Chamber Configuration

The single-chamber layout minimizes component handling and prevents cross-contamination between process steps.

Optimized Spray and Filtration System

EcoCvertex uses controlled spray dynamics combined with efficient filtration to remove contaminants while maintaining stable media quality.

Integrated Drying Technology

Effective drying is essential for downstream assembly and coating operations. EcoCvertex incorporates controlled drying stages to ensure components are process-ready.

Automation and Process Monitoring

Automated cycle control improves repeatability and supports consistent cleaning performance across production batches.

How EcoCvertex Ensures Repeatable Cleaning Results

EcoCvertex treats industrial cleaning as a measurable process rather than a visual outcome.

Key contributors to process stability include:

- Controlled mechanical action

- Consistent thermal management

- Reliable separation of contaminants

- Defined process sequencing

This approach reduces rework, stabilizes downstream operations, and supports compliance with defined cleanliness standards.

Application Areas Where EcoCvertex Delivers Value

EcoCvertex is suitable for a wide range of manufacturing applications, including:

- Automotive and powertrain components

- Precision-machined industrial parts

- E-mobility assemblies

- Components requiring defined cleanliness before assembly

Its flexibility allows manufacturers to adapt the system to varying component types and production volumes.

EcoCvertex vs Conventional Cleaning Systems

| Parameter | Conventional Cleaning | EcoCvertex Cleaning Machine |

| Process Control | Operator dependent | Fully process-controlled |

| Repeatability | Variable | High repeatability |

| Handling | Multiple transfers | Single-chamber processing |

| Cleanliness Consistency | Inconsistent | Measurable and stable |

| Production Integration | Limited | High |

This comparison highlights why EcoCvertex functions as a process solution rather than a basic cleaning unit.

Key Benefits for Modern Manufacturing Plants

Manufacturers using EcoCvertex benefit from:

- Stable and repeatable cleaning results

- Reduced rejection and rework

- Improved downstream process reliability

- Compact system design

- Long-term operational consistency

EcoCvertex supports manufacturers aiming for process reliability and scalable production quality.

Conclusion

The EcoCvertex industrial cleaning machine is engineered to meet the demands of modern precision manufacturing. By integrating multiple cleaning stages into a single, controlled system, it transforms industrial cleaning into a stable and repeatable process.

For manufacturers seeking to improve component quality, reduce variability, and support long-term production efficiency, EcoCvertex delivers a machine-based cleaning solution aligned with real manufacturing requirements.

Frequently Asked Questions (FAQs)

Q.1 What type of components is EcoCvertex suitable for?

- EcoCvertex is suitable for precision-machined components used in automotive, industrial, and e-mobility applications.

Q.2 How does EcoCvertex improve cleaning consistency?

- By controlling mechanical action, temperature, filtration, and drying within a single chamber, EcoCvertex ensures repeatable cleaning results.

Q.3 Can EcoCvertex be integrated into existing production lines?

- Yes. EcoCvertex is designed for easy integration into automated and semi-automated manufacturing environments.

Q.4 Is EcoCvertex suitable for varying production volumes?

A. The system supports flexible cycle configurations, making it suitable for both medium- and high-volume production.