Medical Technology encompasses a wide range of healthcare products used to diagnose, monitor, and treat medical conditions and diseases. This includes devices, machinery, and advanced solutions that improve patient care and are decisive for health outcomes. The cleanliness of medical products such as implants, instruments, cannulas and endoscopes is of highest priority.

Monitored ultrasonic frequency and output

The SBS Ecoclean Group brands Ecoclean and UCM specialize in advanced cleaning systems for medical devices, particularly in the field of endoscopy. UCM offers the UCMPerformanceLine, an ultrasonic multi-chamber immersion cleaning system, which is crucial for maintaining the high standards of cleanliness required for optical lens systems in medical endoscopes. The UCMPerformanceLine is designed for the efficient and precise cleaning of small, delicate parts such as coated lens systems, ensuring they meet stringent cleanliness specifications. The system features modular design for customized cleaning processes, automated parts transport, and is directly connected to a cleanroom. Our UCMPerformanceLine is a great example for focusing on innovative technology, sustainability, and precision: our solutions support the production of high-quality medical devices, contributing to better diagnostic and therapeutic outcomes in healthcare.

Our MedTech Test Center in Monschau

At our Test Center in Monschau, Germany, the SBS Ecoclean Group makes the latest turnkey solutions and innovative parts cleaning and surface processing equipment available for trials. In addition to the well-known infrastructure already available at this location, an exclusive medical technology area has been created to support medical device and implant manufacturers with new advanced cutting-edge solutions.

The MedTech Test Center offers a range of solutions for cleaning and packaging medical implants and instruments. Our complete portfolio, from single-chamber solvent and water-based systems to multi-stage ultrasonic cleaning machines, is used to evaluate the best process for our customers. As one of the biggest challenges for manufacturers in the medical device component industry is keeping up with the ever-changing regulatory environment, the SBS Ecoclean Group offers qualified support to meet the requirements and a recalibration service to bring production up to date. Always in compliance with the latest MDR and FDA regulations.

We are well equipped for your cleaning challenges – with turnkey validated and standardized processes!

Let’s make it all tangible: case studies

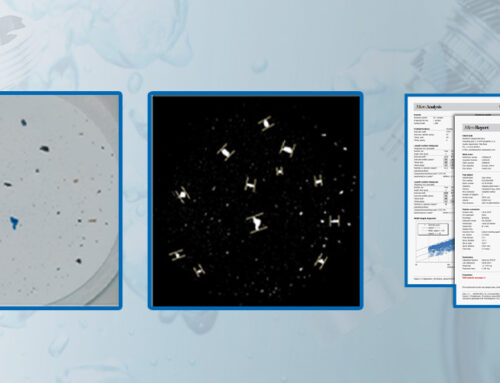

To conclude, we present two case studies, the first one is about Precision Cleaning of optical parts for the medical industry. In the field of medical endoscopy, the quality of optical lens systems is crucial for reliable diagnoses. This case study introduces a renowned manufacturer of coated precision optics who opted for a UCMSmartLine for the final cleaning of precision optics. The company needed a solution that would meet high cleanliness standards and annual throughput targets. Find out why the SBS Ecoclean Group had the best option for the final cleaning step: read the case study.

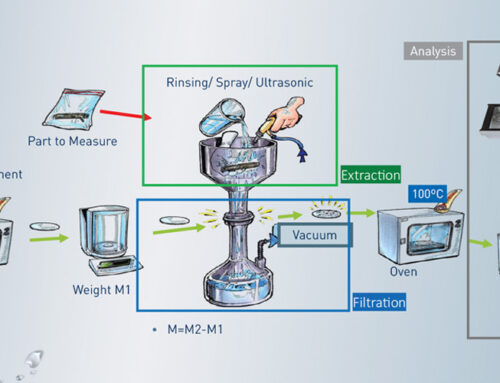

The second case study shows how the newly developed Acoustic Performance Measurement (APM) system provides in-line monitoring of the parameters of ultrasonic frequency and output at each processing station for each parts cleaning batch. Learn how a global manufacturer of knee implants replaced its intermediate and final cleaning equipment with UCMPerformanceLine to meet MDR and FDA regulations and requirements for product safety, process validation, and quality management: read the case study