Table of Contents:

1. Introduction

2. Cleaning & Degreasing Solutions

3. Deburring & Cleaning Solutions

4. Precision Cleaning Solutions

5. Surface Processing Solutions

6. Hydrogen Technology Solutions

7. Reconditioned Machines Solutions

8. Conclusion

9. FAQs

Ecoclean provides a comprehensive range of advanced machine cleaning solutions tailored to meet the diverse needs of industrial manufacturing. With a focus on efficiency, reliability, and innovation, Ecoclean offers a variety of machine cleaning solutions across different categories, each designed to address specific challenges encountered in various industries.

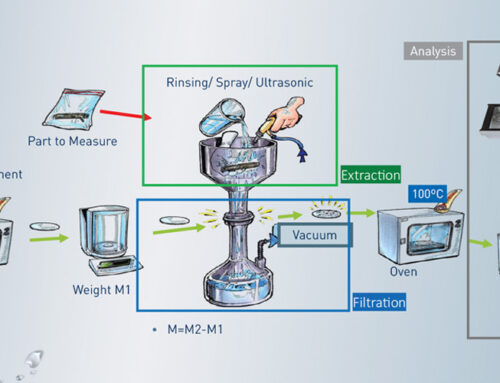

1. Cleaning & Degreasing:

Ecoclean offers state-of-the-art solutions for cleaning and degreasing industrial components, removing oils, greases, and other contaminants to ensure optimal performance and functionality. These cleaning systems utilise various methods such as aqueous cleaning, solvent cleaning, ultrasonic cleaning, and vapour degreasing, providing thorough and efficient cleaning for a wide range of materials and parts.

2. Deburring & Cleaning:

Ecoclean's deburring and cleaning solutions are designed to remove burrs, sharp edges, and other unwanted material from machined parts, ensuring smooth surfaces and precise dimensions. These systems combine deburring and cleaning processes in a single operation, enhancing manufacturing efficiency and product quality.

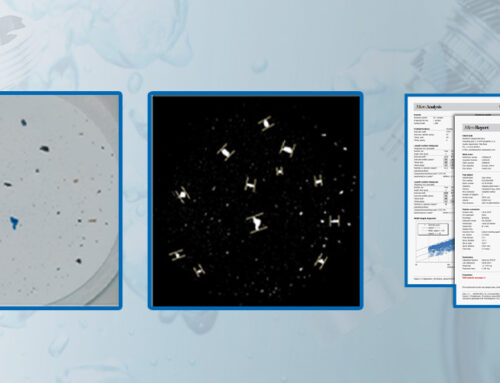

3. Precision Cleaning:

For applications requiring ultra-clean surfaces and stringent cleanliness standards, Ecoclean offers precision cleaning solutions. These advanced systems utilise specialized cleaning methods and technologies to achieve the highest levels of cleanliness, making them ideal for industries such as aerospace, electronics, and medical devices where cleanliness is critical.

Ecoclean's surface processing solutions are tailored to enhance the surface properties of industrial components, including cleaning, etching, and surface activation. These systems improve adhesion, wettability, and other surface characteristics, enabling better performance and functionality of the finished parts.

5. Hydrogen Technology:

As a pioneer in hydrogen-based cleaning technology, Ecoclean offers innovative solutions that utilize hydrogen as a cleaning medium. These hydrogen cleaning systems provide efficient and environmentally friendly cleaning, offering benefits such as reduced energy consumption, shorter cycle times, and improved cleaning results.

6. Reconditioned Machines:

In addition to new cleaning systems, Ecoclean also provides reconditioned machines, offering cost-effective solutions for companies looking to upgrade their cleaning capabilities without investing in new equipment. These reconditioned machines undergo thorough inspection, refurbishment, and testing to ensure reliable performance and quality.

In conclusion, Ecoclean's diverse range of machine cleaning solutions caters to the evolving needs of industrial manufacturing, offering efficient, reliable, and environmentally friendly solutions for cleaning, deburring, precision cleaning, surface processing, hydrogen technology, and reconditioned machines. With a commitment to innovation and customer satisfaction, Ecoclean continues to be a trusted partner for companies seeking to optimize their cleaning processes and enhance product quality.

Frequently Asked Questions (FAQs) about Ecoclean's Machine Cleaning Solutions:

1. What industries can benefit from Ecoclean's Machine cleaning solutions?

– A: Ecoclean's cleaning solutions cater to a wide range of industries including automotive, aerospace, electronics, medical devices, and more, where cleanliness and quality are paramount.

2. What types of contaminants can Ecoclean's cleaning solutions remove?

– A: Ecoclean's solutions are capable of removing various contaminants such as oils, greases, residues, burrs, and other unwanted materials from industrial components.

3. Are Ecoclean's Machine cleaning solutions environmentally friendly?

– A: Yes, Ecoclean prioritizes environmental sustainability and offers solutions that utilize water-based cleaning agents, environmentally safe solvents, and energy-efficient technologies.

4. Can Ecoclean's cleaning solutions handle different types of materials?

– A: Yes, Ecoclean's solutions are designed to handle a wide range of materials including metals, plastics, ceramics, and composites, ensuring compatibility with diverse manufacturing needs.

5. How do I choose the right cleaning solution for my application?

– A: Choosing the right cleaning solution involves considering factors such as the type of contaminants, material compatibility, cleanliness standards, throughput requirements, and budget constraints.

6. What level of cleanliness can Ecoclean's precision cleaning solutions achieve?

– A: Ecoclean's precision cleaning solutions can achieve ultra-clean surfaces with stringent cleanliness standards required for critical applications in industries such as aerospace and electronics.

7. Can Ecoclean customize cleaning solutions for specific applications?

– A: Yes, Ecoclean offers customization options to tailor cleaning solutions to specific application requirements, including size, cleaning method, automation features, and compatibility with existing production lines.

8. What maintenance is required for Ecoclean's cleaning solutions?

– A: Regular maintenance such as cleaning filters, replenishing cleaning agents, and inspecting components for wear and tear is essential to ensure the continued effectiveness and longevity of Ecoclean's cleaning solutions.

9. Are reconditioned machines from Ecoclean as effective as new ones?

– A: Yes, reconditioned machines from Ecoclean undergo thorough inspection, refurbishment, and testing to ensure reliable performance and quality, offering cost-effective solutions for upgrading cleaning capabilities.

10. How does Ecoclean ensure customer satisfaction with its Machine cleaning solutions?

– A: Ecoclean is committed to customer satisfaction through continuous innovation, high-quality products, comprehensive support services, and a team of experienced professionals dedicated to meeting customer needs and expectations.