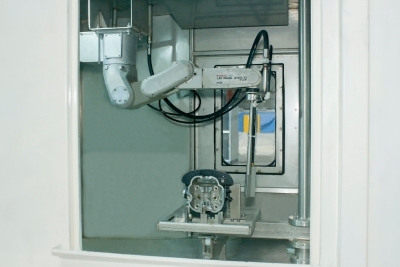

Rotary Indexing Robotic Washer

Indexing the component through multiple cleaning stations:

- Loading: Components are loaded into a stainless-steel pallet fixed on indexing rotary table. Indexing table indexes through 180º and moves component inside the chamber for cleaning.

- Robotic Spray Cleaning: Cleaning media through stainless steel nozzles is sprayed onto components covering all sides and holes of the component.

- Robotic Compressed Air Drying: Components are dried with compressed air using same robot for complete coverage.

- Unloading: Components are manually unloaded after Indexing table again indexes through 180º and stopped at unloading zone.

Related Products from Mhintraa Washers

Rotary Indexing Robotic Washer

Rotary Indexing Robotic Washer [...]